Improved process window

Greater flexibility in molding conditions with consistent performance.

test

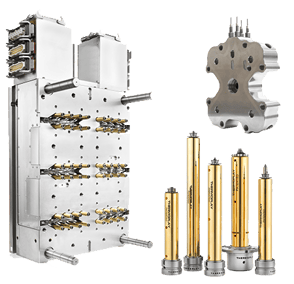

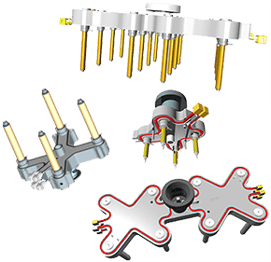

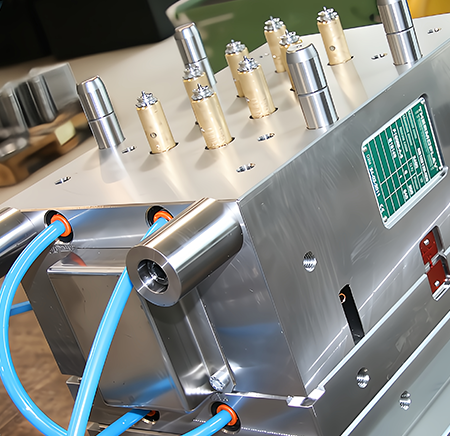

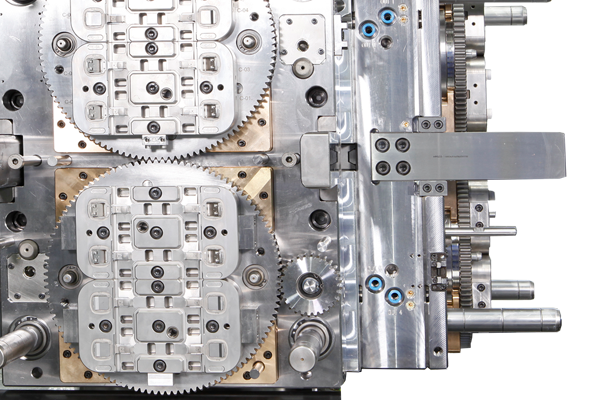

Valve Gate Groups

Hot Runner Systems

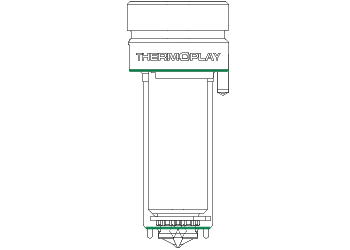

Represent a technological evolution designed to ensure efficiency, reliability and precision in injection systems.

Engineered for compact and versatile integration, these solutions optimize mold performance while simplifying assembly, adjustment and maintenance.

Valve Gate Groups

Hot Runner Systems

-

-

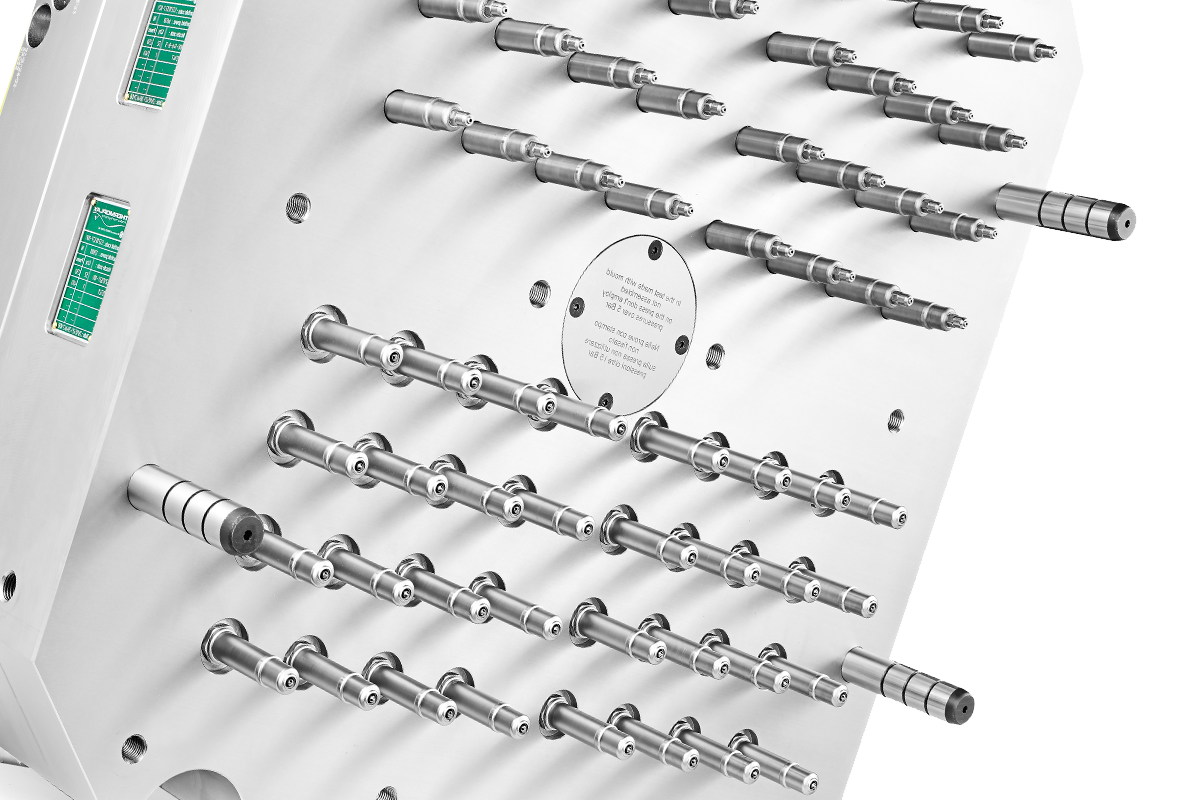

Increased flow channels

Optimized melt flow reduces injection pressure loss and improves efficiency. -

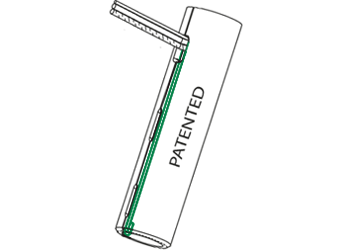

Special patented heater

Ensures a uniform thermal profile for stable production while delivering significant energy savings. -

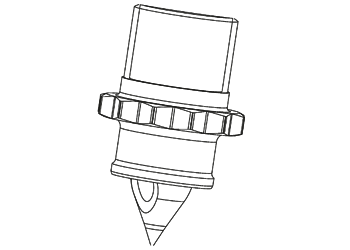

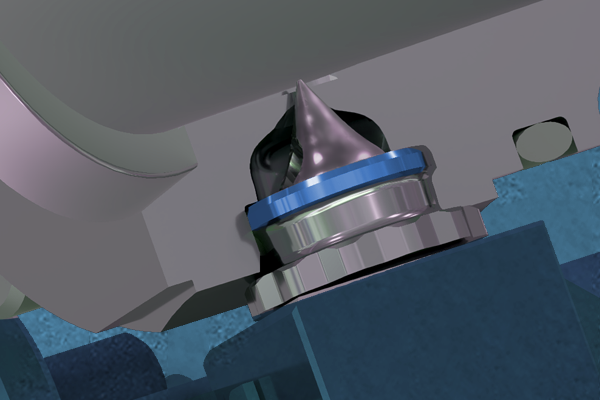

Tips in special steel

Provide optimal thermal conduction and high wear resistance, with a wide range of types suitable for the injection of the most commonly used polymers.Download Material Tables

-

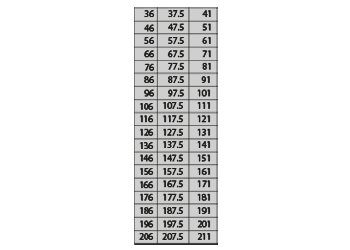

Different lengths available

Adaptable to a variety of applications and requirements. -

Accurate temperature control

Thermocouple positioned close to the tip zone for precise temperature reading. -

Easy maintenance

Heater and thermocouple can be replaced directly on the injection machine, minimizing downtime. -

Double sealing system

Reliable sealing on both the nozzle tip and head ensures safe and stable operation.

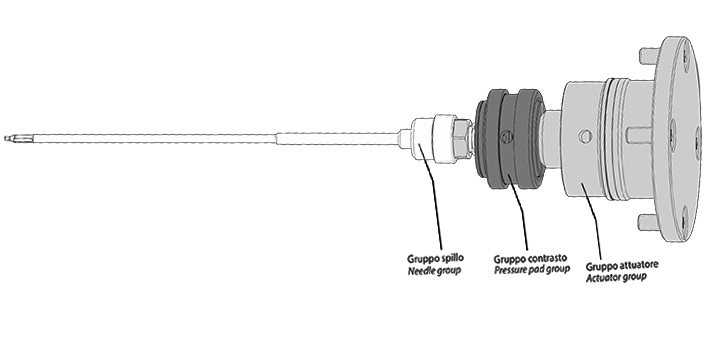

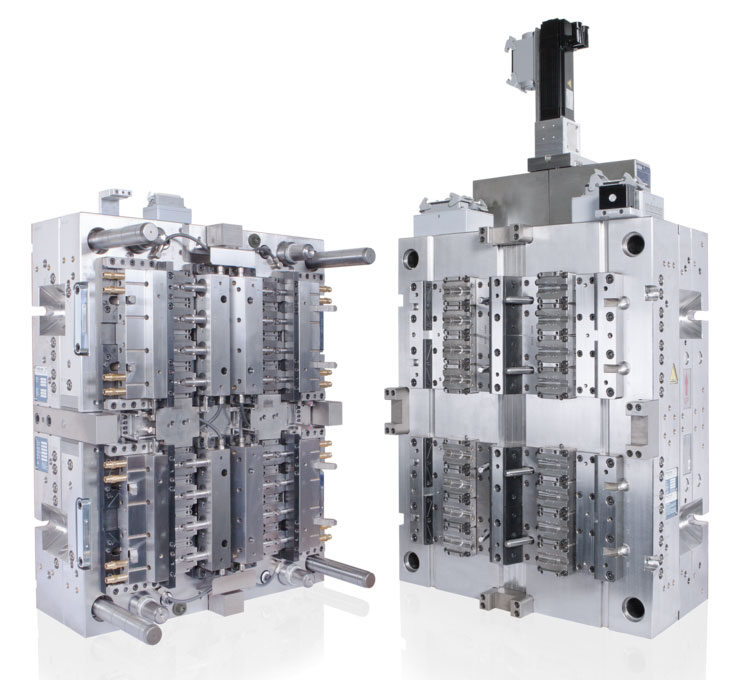

Thermoplay valve gate solutions are designed for compact integration, either directly on the manifold or housed in the back plate.

They feature plate actuator systems for reduced pitch applications, with options for pin adjustment and exclusion.

Each unit includes a piston housing for easier machining and assembly, durable heat-resistant seals, and precision-matched pin and guide components for easy maintenance.

Available for both hydraulic and pneumatic operation, these systems ensure superior leak resistance, multiple pin configurations, and convenient in-mould pin adjustment across most models.

Hydraulic operation

-

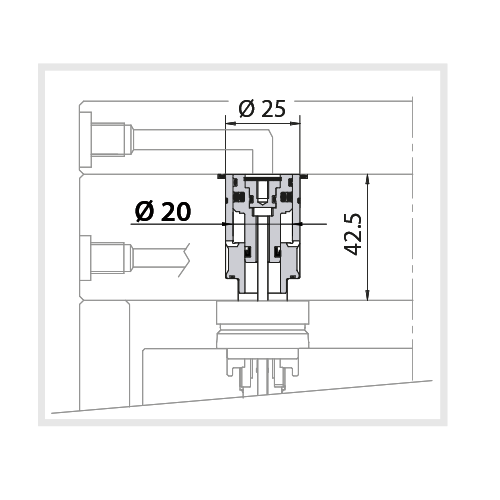

Hydraulic operation SH20-HY

Hydraulic operation SH20-HYNozzle Types

TF3 Ø 12

Pin stroke 7 mm

Ø pin 2.5 mm

Ø bore piston 20 mmTF3/3B/3D/3DSLA/3DSLU Ø 17, Ø 23 - TD3 Ø 18, Ø 22

Pin stroke 10 mm

Ø pin 2.5 mm

Ø bore piston 20 mmOperating Characteristics

Actuation: Hydraulic only

Cylinder Bore: Ø 20 mm

Mounting: In a mould plate 42.5 mm thick, with a bore of Ø 25 mm for each cylinder.

Back plate: Needed with an air channel to operate the cylinder (see catalogue)

Stroke adjustment: Not possible

Pin orientation: Fixed, cannot be oriented.

Pneumatic operation

-

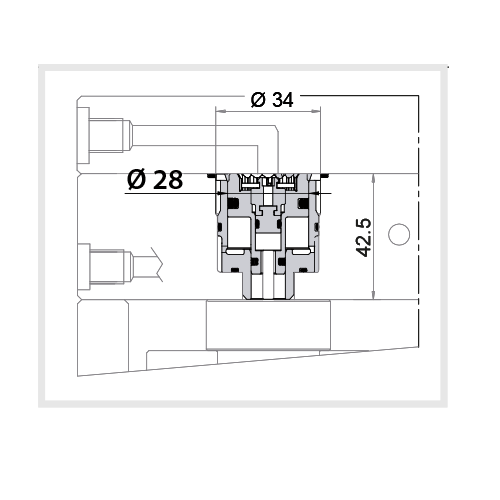

Pneumatic operation S28-PN

Pneumatic operation S28-PNNozzle Types

TF3 Ø 12

Pin stroke 7 mm

Ø pin 2.5 mm

Ø bore piston 28 mmTF3/3B/3D/3DSLA/3DSLU Ø 17, Ø 23 - TD3 Ø 18, Ø 22

Pin stroke 10 mm ±0.75 mm

Ø pin 2.5 mm

Ø bore piston 32 mmFN3T/3BT/3D/3DSLA/3DSLU Ø 32 - TD3 Ø 30

Pin stroke 10 mm ±0.75 mm

Ø pin 3.3 mm

Ø bore piston 28 mmOperating Characteristics

Actuation: Pneumatic only

Cylinder Bore: Ø32 mm

Mounting: In a 42.5 mm thick back plate, with a bore of Ø 34 mm for each cylinder.

Fine Adjustment: Adjusted in 0.05 mm increments by ±0.75 mm.

Adjustment is achieved by a simple adjustment screw located in the back of the cylinder and accessed without removing the mould for the injection moulding machine (depending on the mould design).

Pin Orientation: Optional -

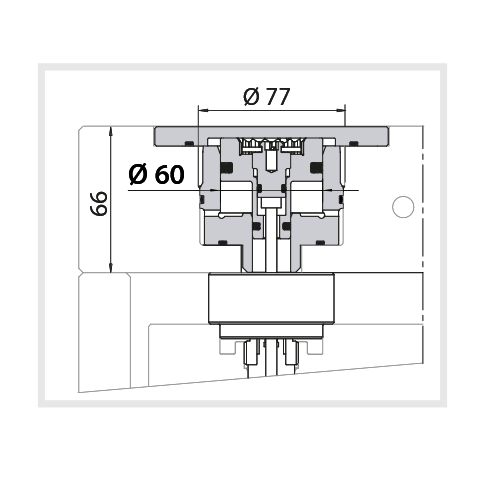

Pneumatic operation S60-PN

Pneumatic operation S60-PNNozzle Types

FN3/3B/3D/3DSLA/3DSLU Ø 46

Pin stroke 16 mm ±0.75 mm

Ø pin 5.8 mm

Ø bore piston 60 mmOperating Characteristics

Actuation: Pneumatic only

Cylinder Bore: Ø60 mm

Mounting: In a 66 mm thick back plate, with a bore of Ø 77 mm for each cylinder.

Fine Adjustment: adjusted in 0.05 mm increments by ±0.75mm.

Adjustment is achieved by a simple adjustment screw located in the back of the cylinder and accessed without removing the mould for the injection moulding machine (depending on the mould design).

Pin Orientation: Optional -

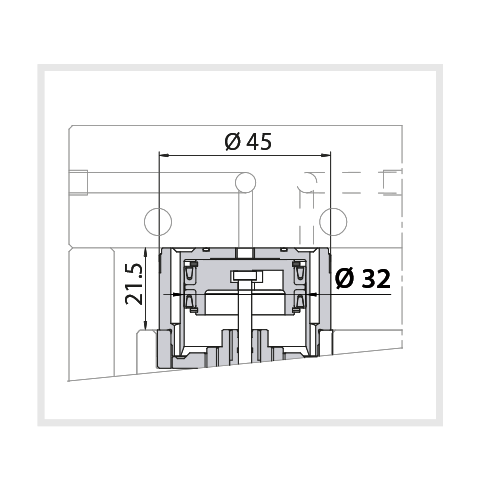

Pneumatic operation K32-PN

Pneumatic operation K32-PNNozzle Types

TF3 Ø 12

Pin stroke 7 mm

Ø pin 2.5 mm

Ø bore piston 32 mmTF3/3B/3D/3DSLA/3DSLU Ø 17, Ø 23 - TD3 Ø 18, Ø 22

Pin stroke MIN 10 mm - MAX 10.5 mm

Ø pin 2.5 mm

Ø bore piston 32 mmFN3T/3BT/3D/3DSLA/3DSLU Ø 32 - TD3 Ø 30

Pin stroke MIN 10 mm - MAX 10.5 mm

Ø pin 3.3 mm

Ø bore piston 32 mmOperating Characteristics

Actuation: Pneumatic only

Cylinder Bore: Ø32 mm

Mounting: Housed within manifold mould plate

Black Plate: Needed with air channels o operate the cylinder (see catalogue)

Pin Orientation: Fixed, cannot be oriented. -

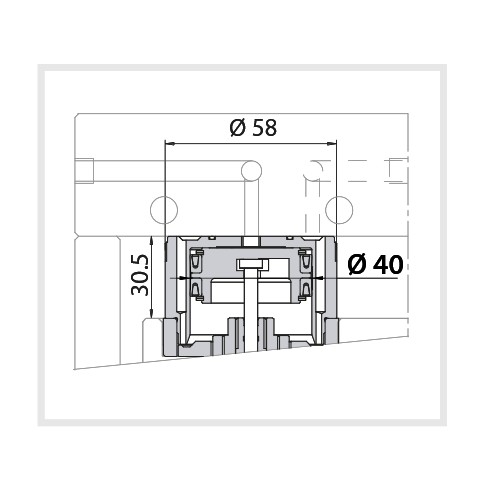

Pneumatic operation K40-PN

Pneumatic operation K40-PNNozzle Types

FN3/3B/3D/3DSLA/3DSLU Ø 46

Pin stroke MIN 16 mm - MAX 17 mm

Ø pin 5.8 mm

Ø bore piston 40 mmOperating Characteristics

Actuation: Pneumatic only

Cylinder Bore: Ø40 mm

Mounting: In manifold mould plate

Black Plate: Needed with an air channels to operate the cylinder (see catalogue)

Stroke Adjustment: Reducing the thickness of the adjustment washer, the pin stroke can be increased by 0.5 mm.

Pin Orientation: Fixed, cannot be oriented.

Hydraulic and Pneumatic Operation

-

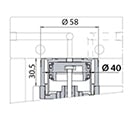

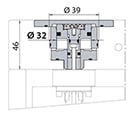

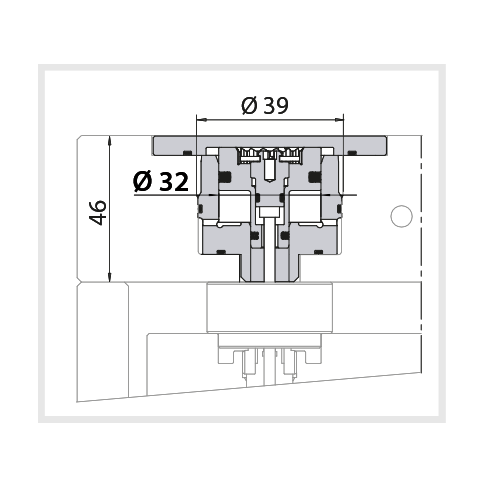

Hydraulic and Pneumatic operation S32-HY/PN

Hydraulic and Pneumatic operation S32-HY/PNNozzle Types

TF3 Ø 12

Pin stroke 7 mm

Ø pin 2.5 mm

Ø bore piston 32 mmTF3/3B/3D/3DSLA/3DSLU Ø 17, Ø 23 - TD3 Ø 18, Ø 22

Pin stroke 10 mm ±0.75 mm

Ø pin 2.5 mm

Ø bore piston 32 mmFN3T/3BT/3D/3DSLA/3DSLU Ø 32 - TD3 Ø 30

Pin stroke 10 mm ±0.75 mm

Ø pin 3.3 mm

Ø bore piston 32 mmOperating Characteristics

Actuation: Pneumatic or Hydraulic

Cylinder Bore: Ø32 mm

Mounting: In a 46 mm thick back plate, with a bore of Ø 39 mm for each cylinder.

Fine Adjustment: Adjusted in 0.05 mm increments by ±0.75 mm.

Adjustment is achieved by a simple adjustment screw located in the back of the cylinder and accessed without removing the mould for the injection moulding machine (depending on the mould design).

Pin Orientation: Optional

| SH20-HY |

|

Nozzle Types TF3/3B/3D/3DSLA/3DSLU Ø 17, Ø 23 - TD3 Ø 18, Ø 22 Operating Characteristics |

Catalog Drawings |

| S28-PN |

|

Nozzle Types TF3/3B/3D/3DSLA/3DSLU Ø 17, Ø 23 - TD3 Ø 18, Ø 22 FN3T/3BT/3D/3DSLA/3DSLU Ø 32 - TD3 Ø 30 Operating Characteristics |

Catalog Drawings

|

| S60-PN |

|

Nozzle Types Operating Characteristics |

Catalog Drawings |

| K32-PN |

|

Nozzle Types TF3/3B/3D/3DSLA/3DSLU Ø 17, Ø 23 - TD3 Ø 18, Ø 22 FN3T/3BT/3D/3DSLA/3DSLU Ø 32 - TD3 Ø 30 Operating Characteristics |

Catalog Drawings |

| K40-PN |

|

Nozzle Types Operating Characteristics |

Catalog Drawings |

| S32-HY/PN |

|

Nozzle Types TF3/3B/3D/3DSLA/3DSLU Ø 17, Ø 23 - TD3 Ø 18, Ø 22 FN3T/3BT/3D/3DSLA/3DSLU Ø 32 - TD3 Ø 30 Operating Characteristics |

Catalog Drawings |

-

Improved process window

Greater flexibility in molding conditions with consistent performance. -

Increased flow channels

Optimized melt flow reduces injection pressure loss and improves efficiency. -

Special patented heater

Ensures a uniform thermal profile for stable production while delivering significant energy savings. -

Tips in special steel

Provide optimal thermal conduction and high wear resistance, with a wide range of types suitable for the injection of the most commonly used polymers.Download Material Tables

-

Different lengths available

Adaptable to a variety of applications and requirements. -

Accurate temperature control

Thermocouple positioned close to the tip zone for precise temperature reading. -

Easy maintenance

Heater and thermocouple can be replaced directly on the injection machine, minimizing downtime. -

Double sealing system

Reliable sealing on both the nozzle tip and head ensures safe and stable operation.

-

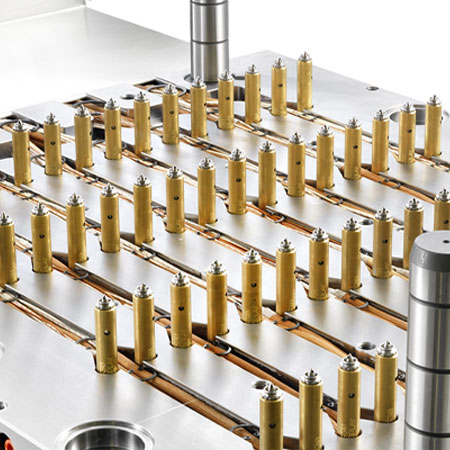

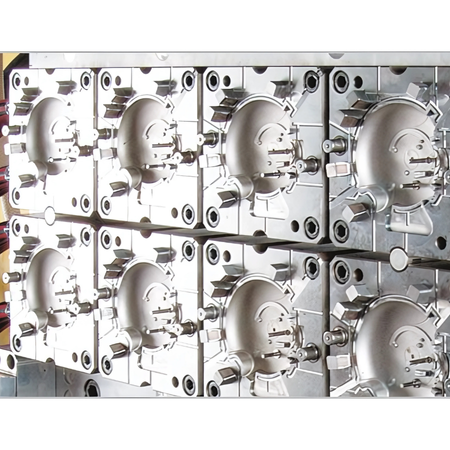

Plate actuated valve gates solutions

Synchronized pneumatic or hydraulic actuation plate for valve gate systems.

Main features:

- Compact valve gate system and actuation.

- Minimal pitch of nozzles and valve gate pins.

- Perfect synchronism in opening and closing the cavities.

- Mechanical adjustment of needle length, independent on each single cavity (PATENTED).

- Ability to release a single pin (with distance between cavities >38mm) (PATENT PENDING).

- Opening/closing cavities, and pin adjustment can be executed on the machine

Technical characteristics:

- Minimum pitch of nozzles:

- with disengaging and pin adjustment devices: 38 mm.

- only with pin adjustment device: 22 mm.

- without any device: 17 mm.

-

Innovation, precision, and reliability

Our hot runner systems are engineered to optimize every stage of the injection molding process, ensuring high performance and consistent quality across all applications.

For detailed technical information and product specifications, please refer to the dedicated section of the technical catalog.

Unlocking More Value for Your Production Line

-

Hot Runner Refurbishment

Hot Runner RefurbishmentHot runner systems are the heart of efficient injection molding — but even the best equipment wears over time. Our refurbishment service restores worn or damaged components to optimal condition, ensuring precise temperature control, improved flow, and consistent product quality. Avoid unplanned downtime and costly replacements while keeping your production running smoothly.

-

Hot Runner Training

Hot Runner TrainingOur two-day training program combines in-depth theoretical instruction with hands-on practice directly in the workshop. It is designed for professionals who want to understand not only the principles of hot runner systems, but also how to install, maintain, and service them effectively.

From Fundamentals to Practical Expertise!

-

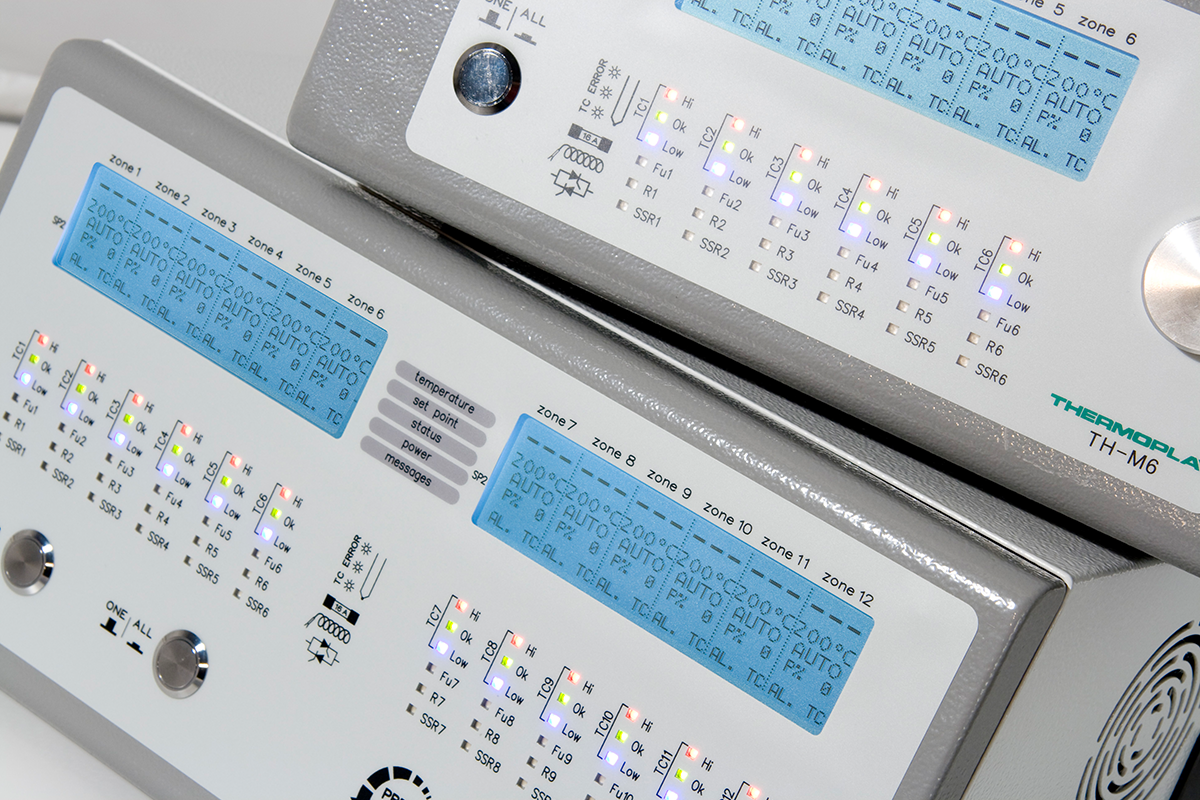

Hot Runner Control Systems

Hot Runner Control SystemsPrecise temperature management is the key to producing consistent, high-quality parts while keeping scrap rates low and profitability high.

Our advanced Gammaflux control systems deliver unmatched accuracy, stability, and user-friendly operation. With intelligent temperature monitoring and adaptive control, you can ensure optimal melt flow, reduce downtime, and increase the overall efficiency of your production process.

Whether you’re running small-scale projects or high-cavity, high-volume production, Gammaflux technology provides the precision and reliability you need to take full control of your hot runner system.

-

Hot Runner Side Gating

Hot Runner Side GatingThe thermal side gate nozzle from Männer proves in demanding, high-volume production that cosmetic gate points, easy assembly, and long-term reliability can be seamlessly combined.

Even in high-cavity molds, this technology ensures consistent performance and superior part quality – making it the ideal choice when precision and appearance matter most.

-

.jpg) Medical Day 2025

Medical Day 2025Medical Day 2025 brought together brilliant minds, inspiring speakers, and a passionate community dedicated to shaping the future of healthcare. From thought-provoking talks to lively networking moments, the day was filled with energy and ideas. Here’s a look back at some of the highlights.

We offer the right refurbishment package –

tailored to your mold's needs.

Whether your mold requires only minor adjustments or a full mechanical and functional overhaul: we offer a flexible range of refurbishment solutions to match your goals, timeline, and budget. All packages are carried out by experienced tooling experts using OEM-level standards and documentation. Planned refurbishment reduces unexpected downtime, lowers total cost of ownership, and keeps your production running efficiently.

-

Mold Refurbishment Light Package

Mold Refurbishment Light PackageOur Light Package focuses on essential components to restore reliable performance with minimal downtime:

-

Full refurbishment of the hot runner system

-

Replacement of guiding and centering elements for FH & MH (AS & DS)

-

Warranty renewal of the hot runner system in accordance with Otto Männer GmbH’s general terms and conditions

This package is ideal for molds still in good condition that require targeted maintenance to ensure consistent part quality and continued process stability.

-

-

Mold Refurbishment Full Package

Mold Refurbishment Full PackageOur most comprehensive package restores your mold to peak performance – ideal for extending lifecycle and maximizing output reliability:

-

Complete replacement of cavity stacks

-

New guiding and centering elements

-

Replacement of all wear and tear parts

-

Full cleaning and inspection of the entire mold

-

Final Operational Test (FOT) to validate performance

-

Warranty renewal with 50% of the original new mold conditions – minimum 1 million cycles guaranteed

This package is recommended when a mold shows extensive wear or reduced precision. It offers a cost-efficient alternative to new mold investment, with high functional reliability.

-

-

.png) Mold Refurbishment Custom Package

Mold Refurbishment Custom PackageTailored refurbishment after a comprehensive mold assessment – based on the exact condition and requirements of your mold.

-

On-site assessment by our experts

-

Customized quotation based on actual wear and condition

-

Refurbishment performed at the MS mold plant, using OEM standards

-

Final Operational Test (FOT) ensures mold readiness

-

Warranty renewal after full refurbishment with 50% of the original warranty conditions – minimum 1 million cycles

Cost transparency & value-added:

-

Refurbishment > €100k → 50% reimbursement of the assessment costs

-

Refurbishment > €200k → 75% reimbursement of the assessment costs

Optional add-ons:

-

Spare parts packages (mold / hot runner)

-

Stand-alone repairs of damaged components (if feasible)

-

Modifications to meet new production or product requirements

This package is ideal for complex, high-value molds where a detailed condition-based approach ensures maximum return on investment.

-

-

Cube Mold Refurbishment ETW Package

Cube Mold Refurbishment ETW PackagePlanned hot runner maintenance can reduce downtime by up to 70%.

-

Mold & Hot Runner Refurbishment Spare Parts Agreement

Mold & Hot Runner Refurbishment Spare Parts AgreementAlways Ready, Always Reliable: A spare parts agreement with Männer or Foboha ensures that essential components are always available to keep your molds running smoothly. By securing predefined parts in advance, you minimize downtime and increase efficiency.

Your benefits at a glance:

-

Rapid availability

Immediate access to critical spare parts – less unplanned downtime, better service performance. -

Cost efficiency

Attractive long-term conditions and pricing through fixed contracts. -

Planning reliability

Simplified scheduling of maintenance and repairs with assured parts supply. -

Lower administrative effort

Reduce time and resources needed for sourcing and procurement - Storage costs are covered by Männer/Foboha

-

-