Precision Meets Efficiency

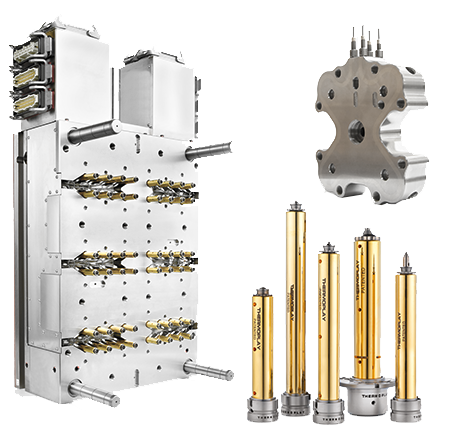

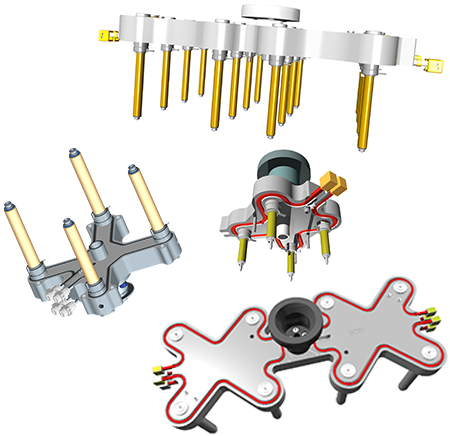

Thermoplay is a top manufacturer of hot runner systems for plastic injection molding, known globally for its innovative solutions. We offer a wide range of in-house designed systems, capable of processing multiple colors and materials simultaneously. Our products include customized solutions for complex applications and a variety of temperature control units to meet molding needs.

Industry Solutions

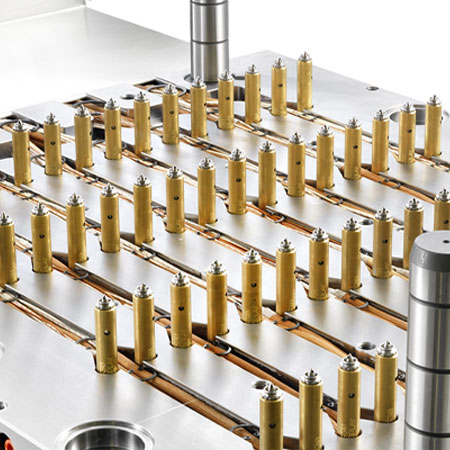

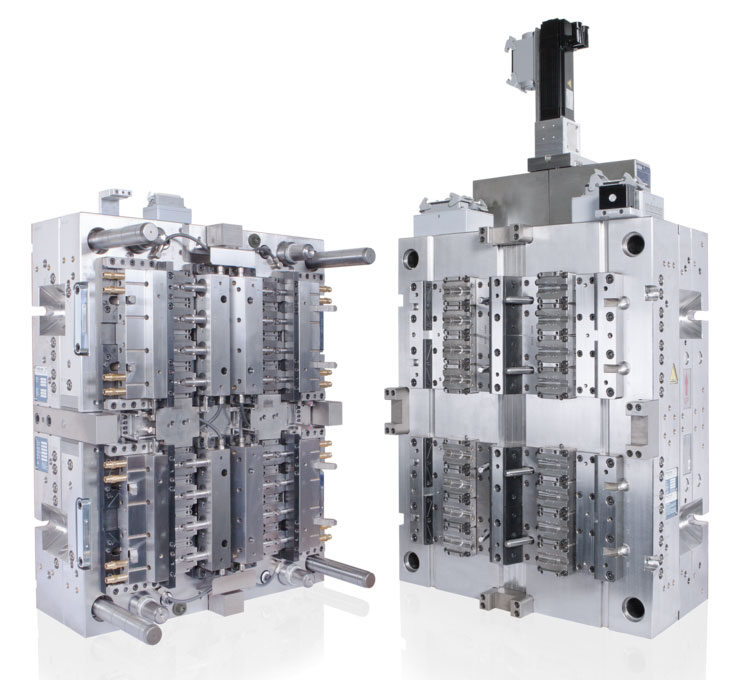

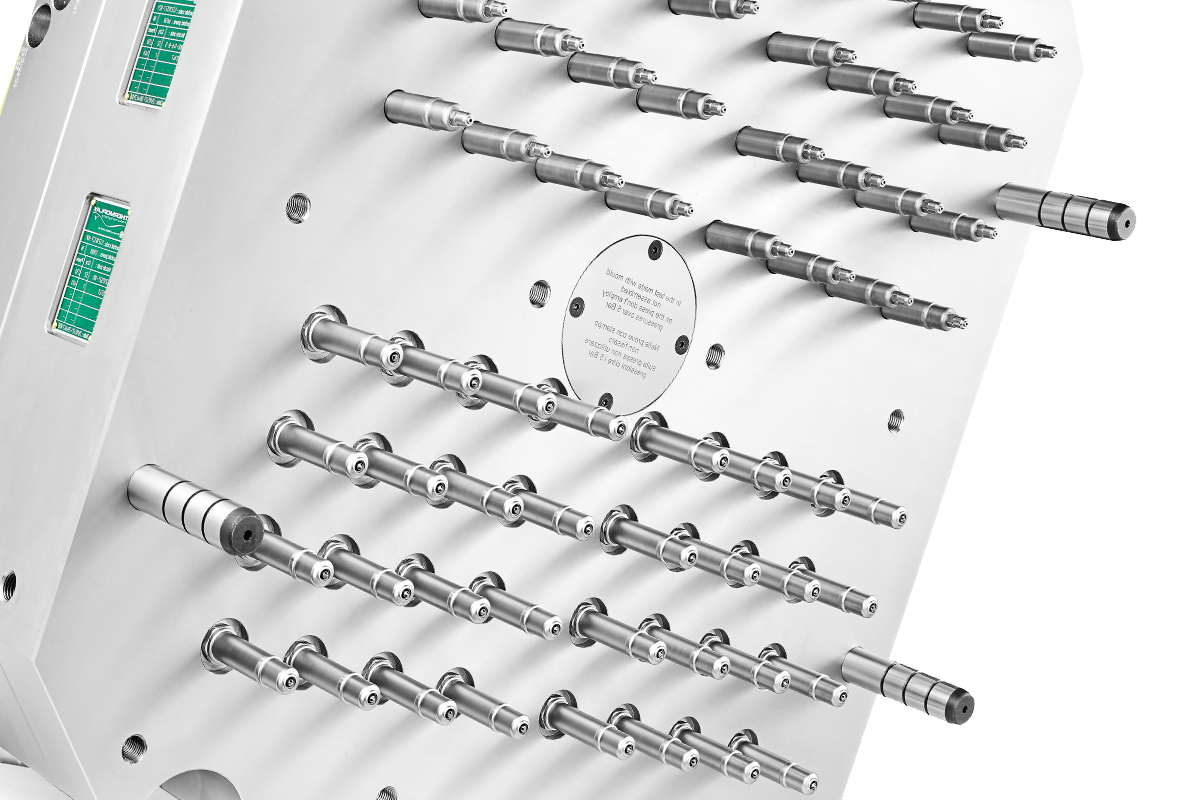

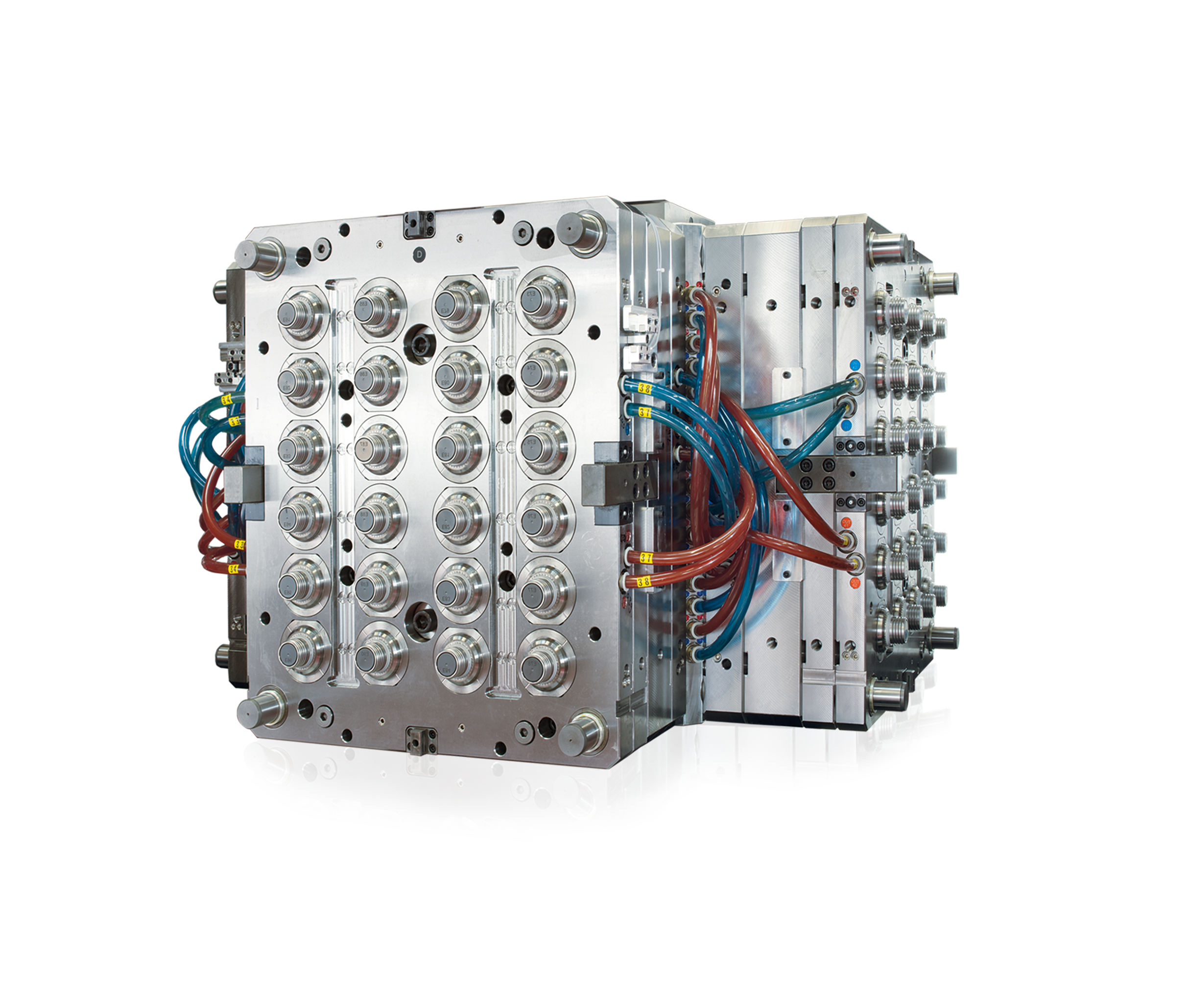

Advanced Hot Runner Systems

Thermoplay’s manufacturing capability is driven by a blend of passion, experience, and versatility. These qualities enable us to consistently deliver high-quality, world-class products that meet the most demanding standards in the plastic injection molding industry.

-

Packaging

-

Medical

Technology -

Technical

Parts -

Automotive

Components

-

Innovation, precision, and reliability

Our hot runner systems are engineered to optimize every stage of the injection molding process, ensuring high performance and consistent quality across all applications.

For detailed technical information and product specifications, please refer to the dedicated section of the technical catalog.

-

Webcreator on line configurator

WEBCREATOR is a web-based design application for configuring Thermoplay Hot Runner Systems with standard nozzles and accessories. This generates high quality CAD 2D and 3D models reducing the production time.

The hot runner system is freely configured in relation to the distance between the nozzles and accounts for the polymer processing conditions. The diameter of the manifold channels, as well as of the descent holes to the nozzles and the injection bushing size are configured to suit.

After configuration the 2D drawings and 3D models are generated in the selected format and sent by email to the user in a single zipped file, which also includes the configuration sheet and part list (in pdf format).

Any configurations made can be modified to generate a new drawing later. WEBCREATOR does not perform any check on the configured system in relation to the injected polymer.

Download Available Configurations

Innovation, precision, and reliability

Our hot runner systems are engineered to optimize every stage of the injection molding process, ensuring high performance and consistent quality across all applications.

For detailed technical information and product specifications, please refer to the dedicated section of the technical catalog.

Let’s Build Something Together

Have a question or idea? We’d love to hear from you.

Smart Solutions, Sustainable Future

-

Quality and Adaptability Certified

Quality and Adaptability CertifiedThermoplay ensures the highest quality at every stage of the production process, from component inspection and machining to assembly and shipping.

The UNI EN ISO 9001 certification confirms our commitment to excellence, adaptability, and continuous improvement, ensuring that our products consistently meet customer requirements and comply with applicable regulations. -

Customer-Focused Innovation

Customer-Focused InnovationA team of experienced researchers and technicians, always attentive to market and customer needs, develops innovative, flexible, and easy-to-manage solutions. Prototypes undergo thorough testing, trials, and simulations to ensure consistent and reliable performance throughout all stages of the production process.

Our technical and commercial department provides fast and targeted support, ensuring the timely delivery of standard systems, manifold plates, and nozzles, guaranteeing continuity, efficiency, and high-quality products for our customers.

-

Sustainability in Action

Sustainability in ActionThermoplay places sustainability at the heart of its operations, using 100% renewable energy, water recirculation systems, LED lighting, and biodegradable materials. The company minimizes waste, supports local products, and demonstrates its commitment to a responsible, environmentally friendly future.

We offer the right refurbishment package –

tailored to your mold's needs.

Whether your mold requires only minor adjustments or a full mechanical and functional overhaul: we offer a flexible range of refurbishment solutions to match your goals, timeline, and budget. All packages are carried out by experienced tooling experts using OEM-level standards and documentation. Planned refurbishment reduces unexpected downtime, lowers total cost of ownership, and keeps your production running efficiently.

-

Mold Refurbishment Light Package

Mold Refurbishment Light PackageOur Light Package focuses on essential components to restore reliable performance with minimal downtime:

-

Full refurbishment of the hot runner system

-

Replacement of guiding and centering elements for FH & MH (AS & DS)

-

Warranty renewal of the hot runner system in accordance with Otto Männer GmbH’s general terms and conditions

This package is ideal for molds still in good condition that require targeted maintenance to ensure consistent part quality and continued process stability.

-

-

Mold Refurbishment Full Package

Mold Refurbishment Full PackageOur most comprehensive package restores your mold to peak performance – ideal for extending lifecycle and maximizing output reliability:

-

Complete replacement of cavity stacks

-

New guiding and centering elements

-

Replacement of all wear and tear parts

-

Full cleaning and inspection of the entire mold

-

Final Operational Test (FOT) to validate performance

-

Warranty renewal with 50% of the original new mold conditions – minimum 1 million cycles guaranteed

This package is recommended when a mold shows extensive wear or reduced precision. It offers a cost-efficient alternative to new mold investment, with high functional reliability.

-

-

.png) Mold Refurbishment Custom Package

Mold Refurbishment Custom PackageTailored refurbishment after a comprehensive mold assessment – based on the exact condition and requirements of your mold.

-

On-site assessment by our experts

-

Customized quotation based on actual wear and condition

-

Refurbishment performed at the MS mold plant, using OEM standards

-

Final Operational Test (FOT) ensures mold readiness

-

Warranty renewal after full refurbishment with 50% of the original warranty conditions – minimum 1 million cycles

Cost transparency & value-added:

-

Refurbishment > €100k → 50% reimbursement of the assessment costs

-

Refurbishment > €200k → 75% reimbursement of the assessment costs

Optional add-ons:

-

Spare parts packages (mold / hot runner)

-

Stand-alone repairs of damaged components (if feasible)

-

Modifications to meet new production or product requirements

This package is ideal for complex, high-value molds where a detailed condition-based approach ensures maximum return on investment.

-

-

Cube Mold Refurbishment ETW Package

Cube Mold Refurbishment ETW PackagePlanned hot runner maintenance can reduce downtime by up to 70%.

-

Mold & Hot Runner Refurbishment Spare Parts Agreement

Mold & Hot Runner Refurbishment Spare Parts AgreementAlways Ready, Always Reliable: A spare parts agreement with Männer or Foboha ensures that essential components are always available to keep your molds running smoothly. By securing predefined parts in advance, you minimize downtime and increase efficiency.

Your benefits at a glance:

-

Rapid availability

Immediate access to critical spare parts – less unplanned downtime, better service performance. -

Cost efficiency

Attractive long-term conditions and pricing through fixed contracts. -

Planning reliability

Simplified scheduling of maintenance and repairs with assured parts supply. -

Lower administrative effort

Reduce time and resources needed for sourcing and procurement - Storage costs are covered by Männer/Foboha

-

-

About THERMOPLAY

THERMOPLAY, with its HQ in the industrial area of Pont-Saint-Martin in Aosta, Italy, is a leading manufacturer of hot runner systems for the plastic injection moulding industry. As a result of continuous product development and considerable investment, Thermoplay is considered a global leader in hot runner system solutions.

Today, there are 179 employees in the manufacturing plant, which covers a surface of 11,000 square meters. Thermoplay is represented with sales and technical support teams in 48 countries.

Thermoplay was founded in 1963 as a precision mechanical workshop, starting its activity with the production of molds.

The first hot runner system was developed and patented in 1973, paving the way for a new phase of technological advancement.

The 1995 thanks to the success achieved among mold makers and users, Thermoplay officially came to life as a company specialized in hot runner systems.

During 1996, the company focused its activity exclusively on the development and production of hot runner systems.

In the early 2000s Thermoplay began a path of international expansion, opening subsidiaries in Europe and Brazil.

In 2008 It doubled its production capacity and expanded its facilities, strengthening its presence in the global market.

In the years 2008-2014 the company consolidated its position as an international leader in hot runner systems, opening subsidiaries in China and India.

In 2015 Thermoplay became part of Barnes Molding Solutions, a business unit of Barnes Group that brings together leading companies in the sector such as Männer, Foboha, Synventive, Priamus, and Gammaflux.

Thermoplay is recognized globally as a leading manufacturer of hot runner systems, offering innovative in-house designed solutions, multi-material and multi-color processing, customized applications, and advanced temperature control units.

Better Solutions for a Better Tomorrow

High-Performance Hot Runner Systems Since 1973, Thermoplay has been dedicated to the design and manufacture of high-performance hot runner systems for standard and specialty injection molding machines that meet every type of manufacturing need for complex markets and applications. As a global leader in hot runner systems for plastic injection molding, we combine extensive knowledge, innovative approaches, and personalized support to help bring leading-edge products to market.

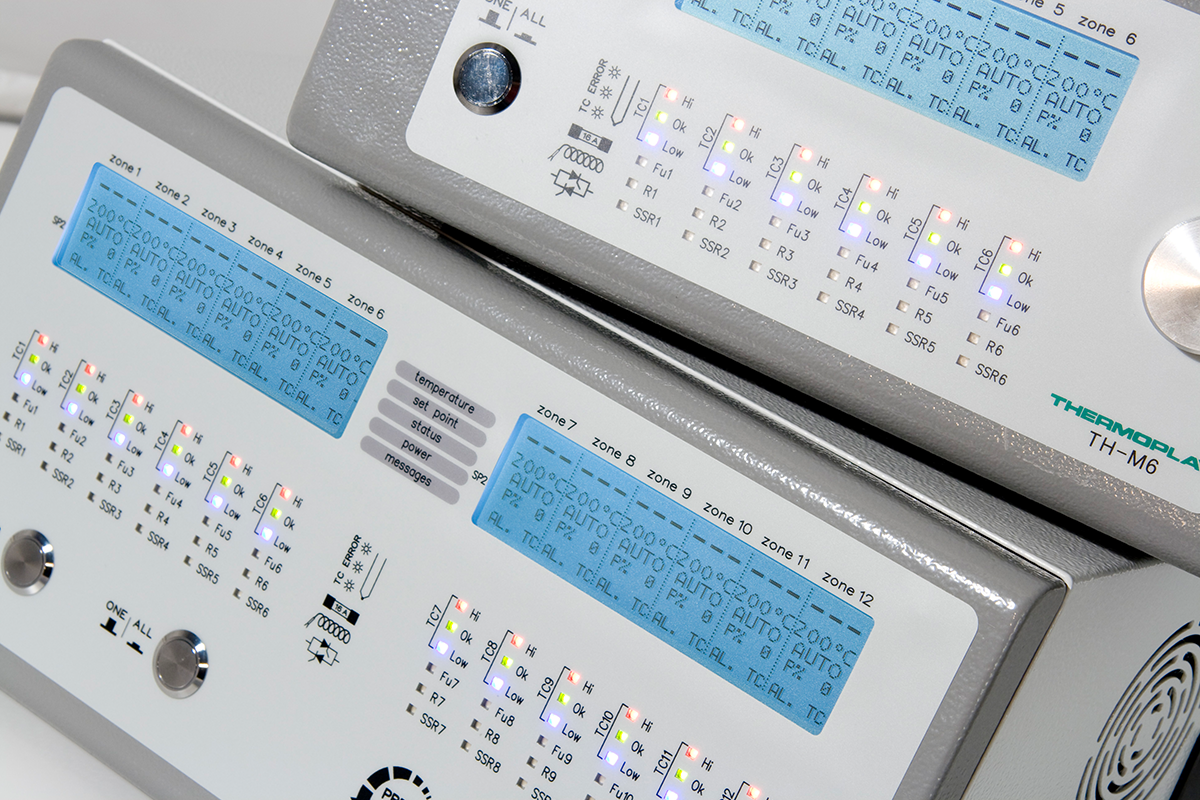

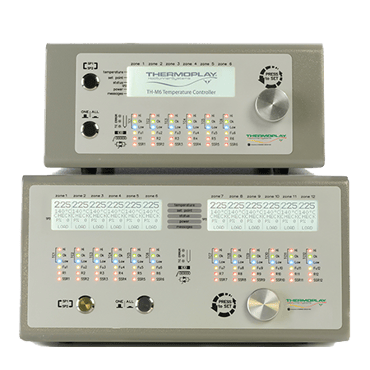

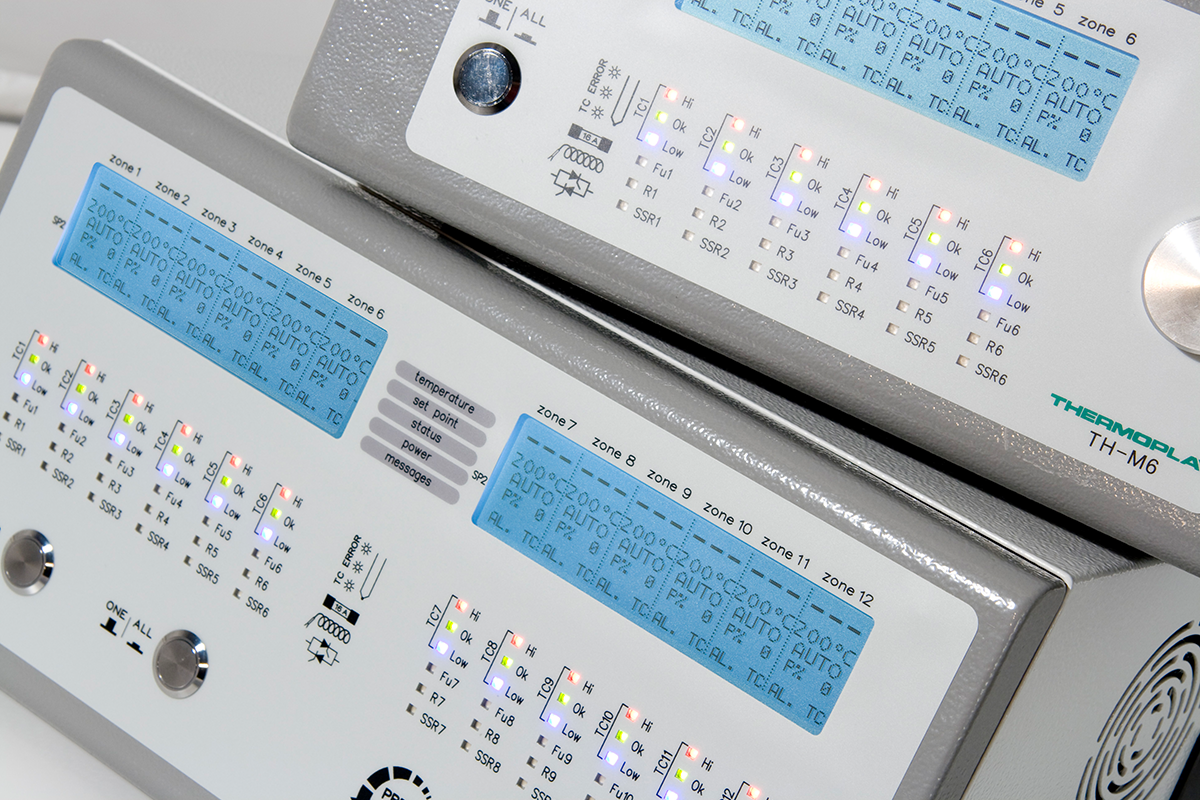

Experience the Thermoplay Difference

Even when our customers have identified the perfect process, an injection molding machine is a living, ever-changing force with variables constantly threatening that process.

Thermoplay temperature controllers take the stress of managing those variables away.

-

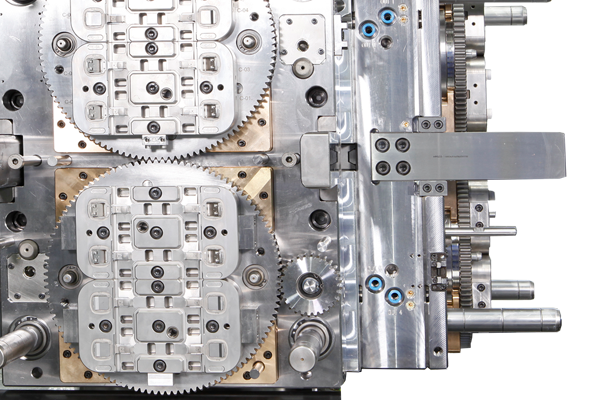

Explore the Future of Mold Technology

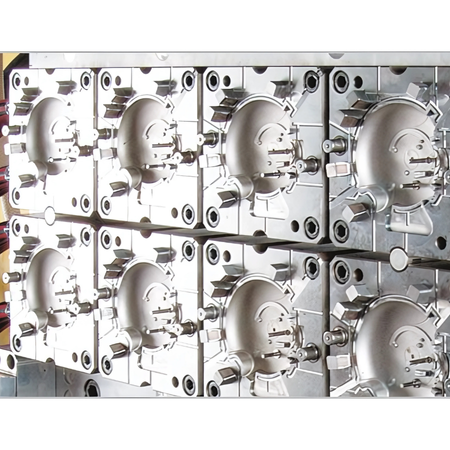

FOBOHA’s innovative cube mold systems use a rotating mold base to combine molding, cooling, and assembly in one tool. This multi-stage process cuts cycle times by up to 30% and maximizes machine utilization—delivering higher output and lower production costs.

Ideal for complex, multi-material parts in industries like packaging, medical, and automotive, FOBOHA’s cube molds offer precision, flexibility, and integrated process solutions.