test

Nature As Our Main Ally

Sustainability at Thermoplay

Our injection molding system offers modular components for simplified maintenance and a consistent thermal profile thanks to our special patented heater. Sintered special steel tips provide optimal thermal conductivity and exceptional wear resistance. With variable length options and single nozzles compatible with all tip types, we offer flexibility and ease of use. In addition, our color change option allows smooth transitions between materials during production.

-

Clean Energy

Energy is at the core of our processes. In 2011, Thermoplay installed a rooftop solar panel system with three inverters. The 860 panels can generate 198 kWp, producing an average of over 185,000 kWh per year. This reduces our environmental footprint by avoiding carbon dioxide emissions from conventional power generation.

The energy produced is fully consumed by the manufacturing department, saving 91,770 kg of CO₂ annually. Today, 100% of Thermoplay’s energy comes from renewable sources, with 90% produced locally in the Valle d’Aosta region via wind and hydroelectric plants, and the remainder generated by our self-consumed solar system.

-

Zero Waste

A water recirculation system is employed for cutting machines, recovering wastewater and filtering it for reuse in the high-pressure pump before returning it to the cutting tank. The system has a treatment capacity of up to 670 liters per hour, minimizing water waste and supporting circular resource management.

-

Efficient Water Cycle

Most machines in the manufacturing department are equipped with water recovery systems that separate water from emulsified oils. This recovered water is then returned to the hydraulic systems of tooling machines, allowing multiple uses of the same resource and reducing overall water consumption.

-

Sustainable Lighting

98% of the lighting in our facilities is provided by energy-efficient LED sources, resulting in a significant reduction of electricity consumption by 60%. This upgrade not only lowers operational costs but also supports our environmental goals by minimizing energy waste. The LED system is carefully designed to provide consistent illumination, ensuring that all work areas maintain optimal visibility and safety standards for employees. In addition, the long lifespan of LED technology reduces maintenance needs, further enhancing overall efficiency and sustainability across our production facilities.

-

Conscious Choices

Plastic bottle usage has been reduced by 90% through the installation of purification and water dispensing systems connected to the public drinking water network, with reusable containers for employees.

Additional initiatives include:

-

Hot drink cups and stirrers made from biodegradable and compostable materials.

-

Snacks and other consumables sourced from local Valle d’Aosta products, supporting regional agriculture and promoting the conservation of local heritage.

-

-

Next Steps Towards a Sustainable Future

The company continues to invest in eco-friendly technologies and innovative solutions, combining high-performance manufacturing with a deep respect for the environment. Every improvement in energy efficiency, waste reduction, and sustainable sourcing contributes to a responsible and forward-looking production philosophy, setting the standard for a sustainable industrial future.

-

Next Steps Towards a Sustainable Future

The company continues to invest in eco-friendly technologies and innovative solutions, combining high-performance manufacturing with a deep respect for the environment. Every improvement in energy efficiency, waste reduction, and sustainable sourcing contributes to a responsible and forward-looking production philosophy, setting the standard for a sustainable industrial future.

Contact Us.

Smart Solutions, Sustainable Future

-

Quality and Adaptability Certified

Quality and Adaptability CertifiedThermoplay ensures the highest quality at every stage of the production process, from component inspection and machining to assembly and shipping.

The UNI EN ISO 9001 certification confirms our commitment to excellence, adaptability, and continuous improvement, ensuring that our products consistently meet customer requirements and comply with applicable regulations. -

Customer-Focused Innovation

Customer-Focused InnovationA team of experienced researchers and technicians, always attentive to market and customer needs, develops innovative, flexible, and easy-to-manage solutions. Prototypes undergo thorough testing, trials, and simulations to ensure consistent and reliable performance throughout all stages of the production process.

Our technical and commercial department provides fast and targeted support, ensuring the timely delivery of standard systems, manifold plates, and nozzles, guaranteeing continuity, efficiency, and high-quality products for our customers.

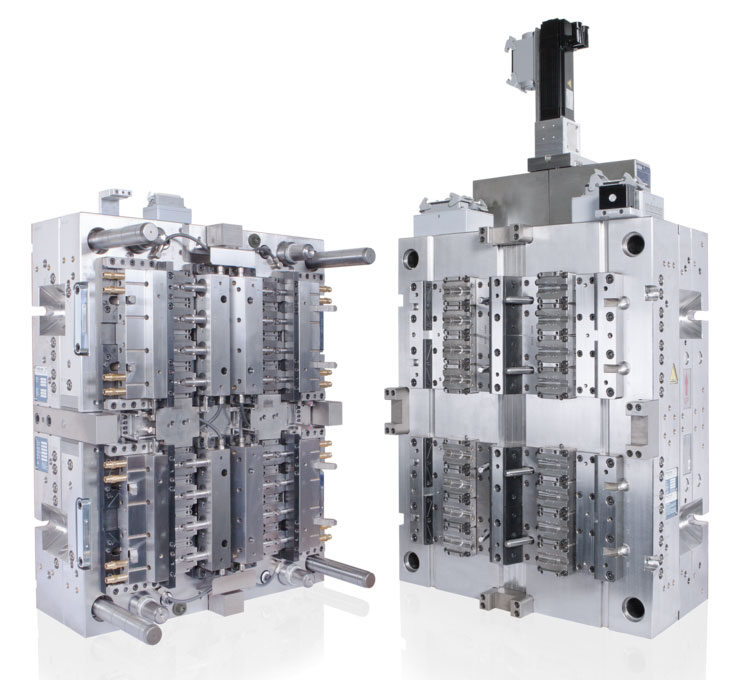

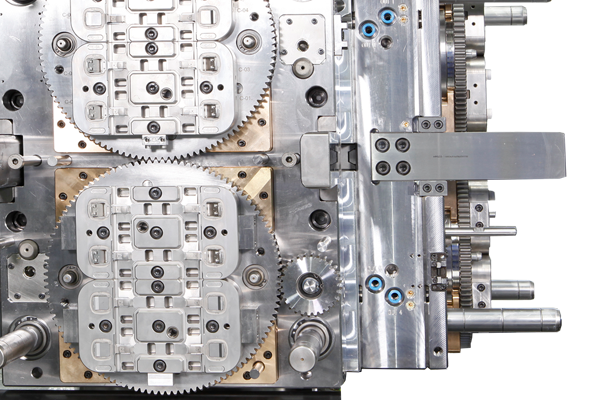

We offer the right refurbishment package –

tailored to your mold's needs.

Whether your mold requires only minor adjustments or a full mechanical and functional overhaul: we offer a flexible range of refurbishment solutions to match your goals, timeline, and budget. All packages are carried out by experienced tooling experts using OEM-level standards and documentation. Planned refurbishment reduces unexpected downtime, lowers total cost of ownership, and keeps your production running efficiently.

-

Mold Refurbishment Light Package

Mold Refurbishment Light PackageOur Light Package focuses on essential components to restore reliable performance with minimal downtime:

-

Full refurbishment of the hot runner system

-

Replacement of guiding and centering elements for FH & MH (AS & DS)

-

Warranty renewal of the hot runner system in accordance with Otto Männer GmbH’s general terms and conditions

This package is ideal for molds still in good condition that require targeted maintenance to ensure consistent part quality and continued process stability.

-

-

Mold Refurbishment Full Package

Mold Refurbishment Full PackageOur most comprehensive package restores your mold to peak performance – ideal for extending lifecycle and maximizing output reliability:

-

Complete replacement of cavity stacks

-

New guiding and centering elements

-

Replacement of all wear and tear parts

-

Full cleaning and inspection of the entire mold

-

Final Operational Test (FOT) to validate performance

-

Warranty renewal with 50% of the original new mold conditions – minimum 1 million cycles guaranteed

This package is recommended when a mold shows extensive wear or reduced precision. It offers a cost-efficient alternative to new mold investment, with high functional reliability.

-

-

.png) Mold Refurbishment Custom Package

Mold Refurbishment Custom PackageTailored refurbishment after a comprehensive mold assessment – based on the exact condition and requirements of your mold.

-

On-site assessment by our experts

-

Customized quotation based on actual wear and condition

-

Refurbishment performed at the MS mold plant, using OEM standards

-

Final Operational Test (FOT) ensures mold readiness

-

Warranty renewal after full refurbishment with 50% of the original warranty conditions – minimum 1 million cycles

Cost transparency & value-added:

-

Refurbishment > €100k → 50% reimbursement of the assessment costs

-

Refurbishment > €200k → 75% reimbursement of the assessment costs

Optional add-ons:

-

Spare parts packages (mold / hot runner)

-

Stand-alone repairs of damaged components (if feasible)

-

Modifications to meet new production or product requirements

This package is ideal for complex, high-value molds where a detailed condition-based approach ensures maximum return on investment.

-

-

Cube Mold Refurbishment ETW Package

Cube Mold Refurbishment ETW PackagePlanned hot runner maintenance can reduce downtime by up to 70%.

-

Mold & Hot Runner Refurbishment Spare Parts Agreement

Mold & Hot Runner Refurbishment Spare Parts AgreementAlways Ready, Always Reliable: A spare parts agreement with Männer or Foboha ensures that essential components are always available to keep your molds running smoothly. By securing predefined parts in advance, you minimize downtime and increase efficiency.

Your benefits at a glance:

-

Rapid availability

Immediate access to critical spare parts – less unplanned downtime, better service performance. -

Cost efficiency

Attractive long-term conditions and pricing through fixed contracts. -

Planning reliability

Simplified scheduling of maintenance and repairs with assured parts supply. -

Lower administrative effort

Reduce time and resources needed for sourcing and procurement - Storage costs are covered by Männer/Foboha

-

-