Shaping innovation, molding success

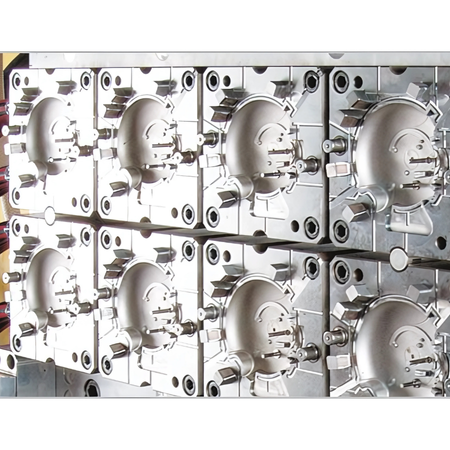

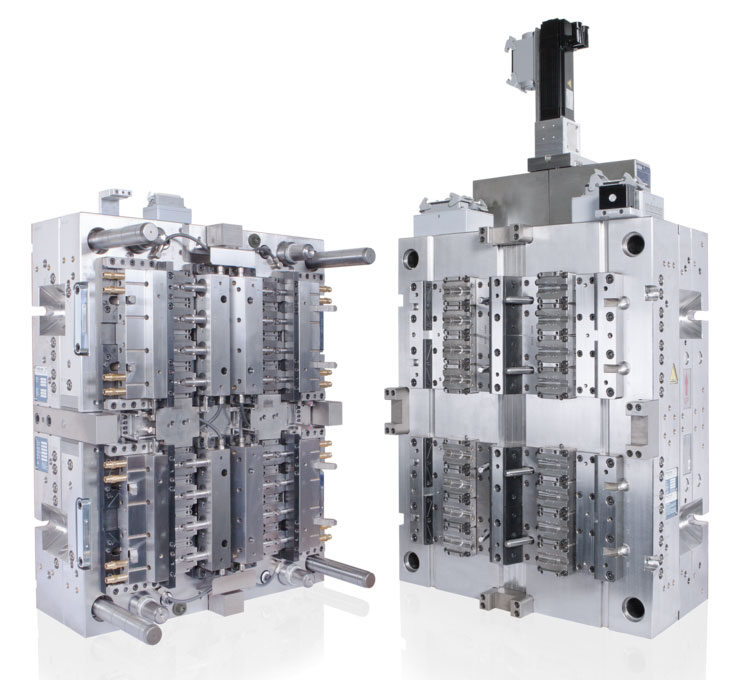

It's our mission. Thermoplay is a recognized leader in the production of hot runner systems for plastic injection molding. From local roots to a global presence, our growth has been driven by strategic investments, continuous innovation, and a strong commitment to excellence. Today, we are recognized in Italy and worldwide as a trusted benchmark for quality, reliability, and technological vision.

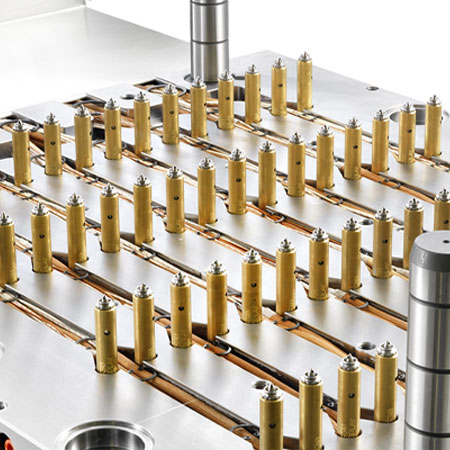

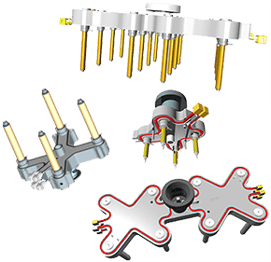

At the heart of our success is a team of highly skilled researchers and engineers, attentive to the challenges of a rapidly evolving market. We design hot runner solutions that are flexible, user-friendly and high-performing, validating each prototype through advanced simulations, diverse plastic material testing, and rigorous trials. The outcome: systems that guarantee efficiency, reliability and lasting value for our customers’ manufacturing processes.

.png)