Advanced Injection Molding Solutions: Efficiency and Versatility

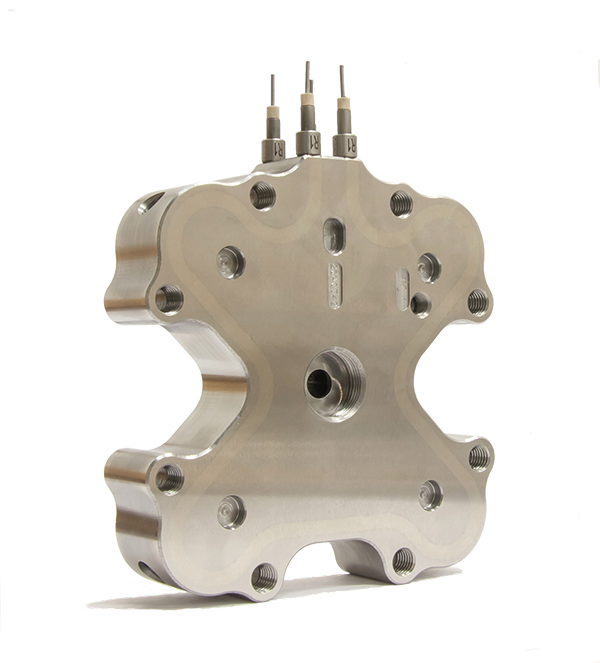

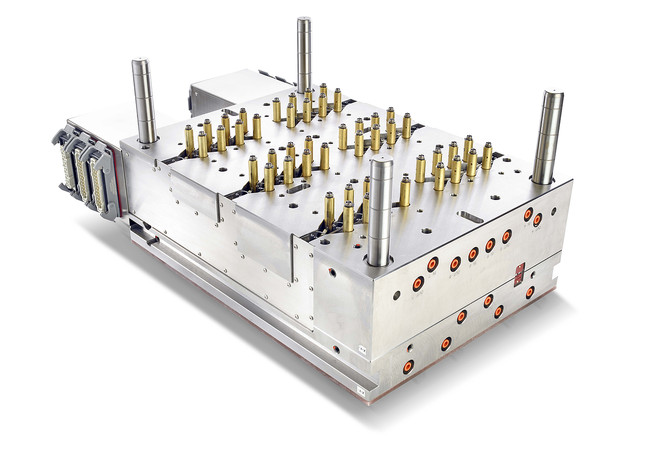

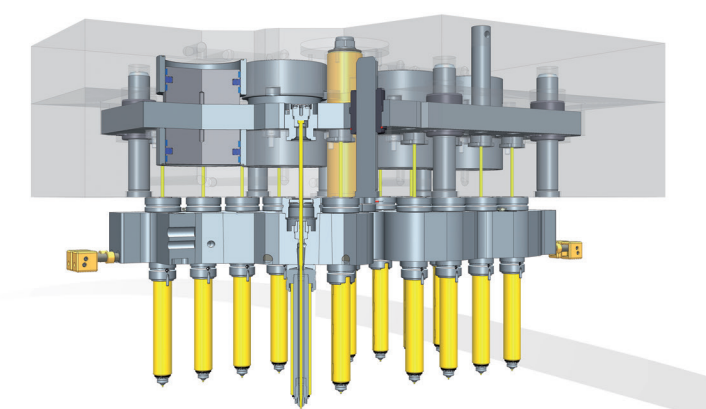

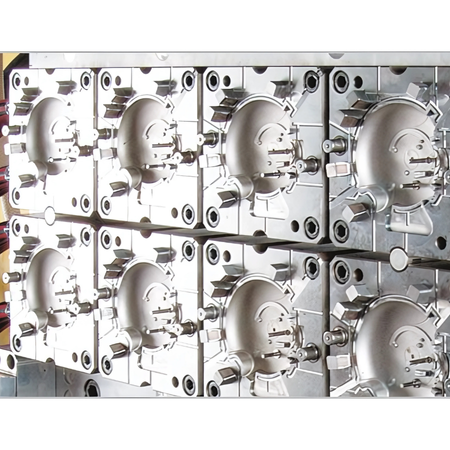

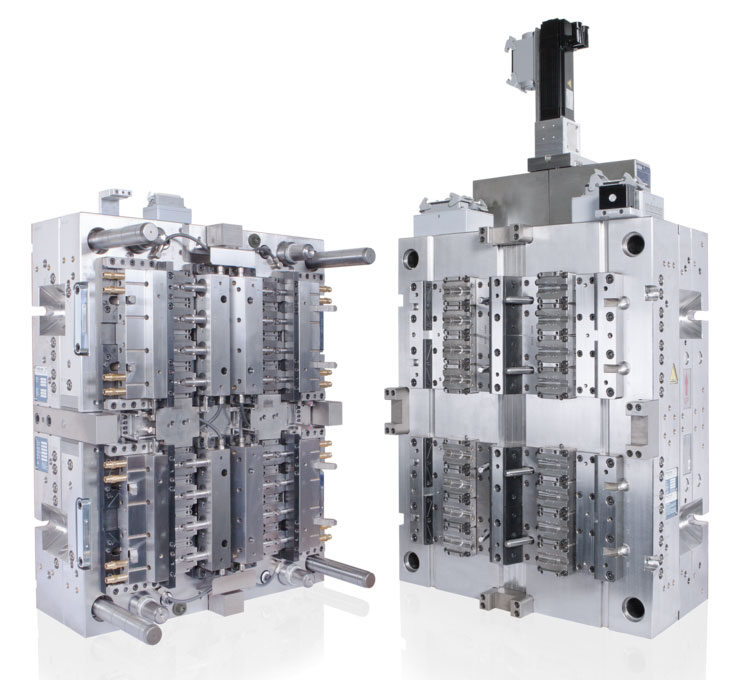

Thermoplay nozzles are designed with modular components, making maintenance fast and efficient since parts can be replaced directly inside the machine. Thanks to our patented heater, they ensure a constant thermal profile and significant energy savings, while tips in special sintered steel provide excellent thermal conductivity and long-lasting wear resistance.

Available in different lengths and with single nozzles compatible with all tip types, they guarantee maximum flexibility. The color change option further enhances productivity, allowing smooth transitions between materials during production.

Our nozzle series includes:

-

TF/FN: suitable for all thermoplastics

-

TD/DN: simple design and easy manufacturing of nozzle seats

-

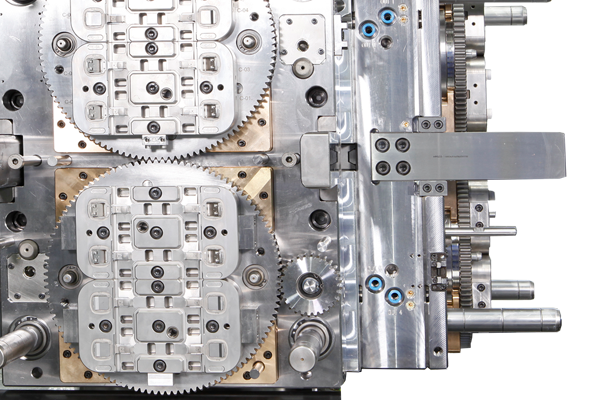

KS: standard multi-tip and side-gate solutions

.jpg)

.png)