Barnes Molding Solutions

We unite the strengths of six renowned brands – Männer, Foboha, Synventive, Thermoplay, Priamus, and Gammaflux – each of which has developed pioneering products and solutions for the plastics industry throughout its history.

To meet the global challenges of the future, we are combining our extensive know-how and technological expertise from different markets and regions. This creates space for new ideas and innovation – while providing our customers around the world with consistent standards, reliable quality, and access to global resources, regardless of where they manufacture.

Molding Solutions

We unite the strengths of six renowned brands – Männer, Foboha, Synventive, Thermoplay, Priamus, and Gammaflux – each of which has developed pioneering products and solutions for the plastics industry throughout its history.

To meet the global challenges of the future, we are combining our extensive know-how and technological expertise from different markets and regions. This creates space for new ideas and innovation – while providing our customers around the world with consistent standards, reliable quality, and access to global resources, regardless of where they manufacture.

Six strong brands –

One shared promise

Foboha, Männer, Synventive, Thermoplay, Priamus, and Gammaflux stand for quality, innovation, and trust in the plastics industry.

Each is among the leading providers in its field.

Together, we are Molding Solutions –

your partner for tooling, hot runner systems, and control technologies in industrial injection molding.

-

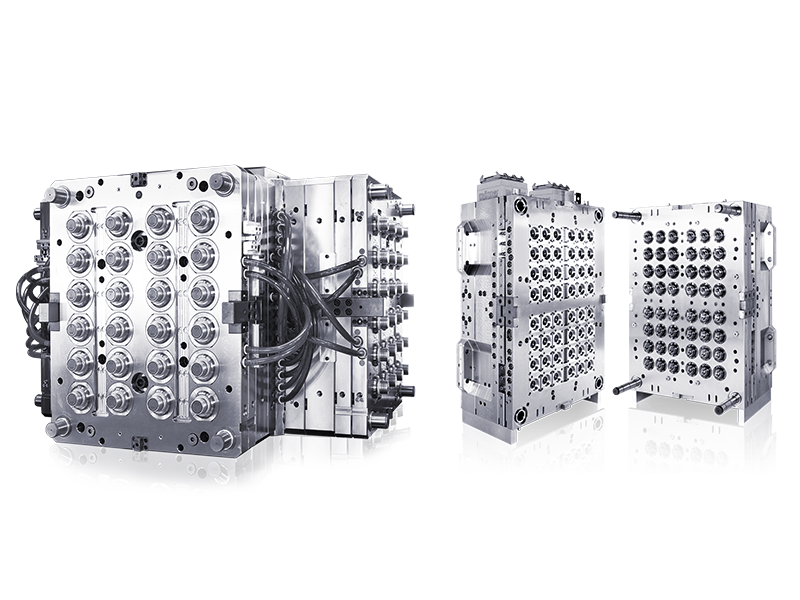

For Multicavity Applications Molds

For Multicavity Applications Molds -

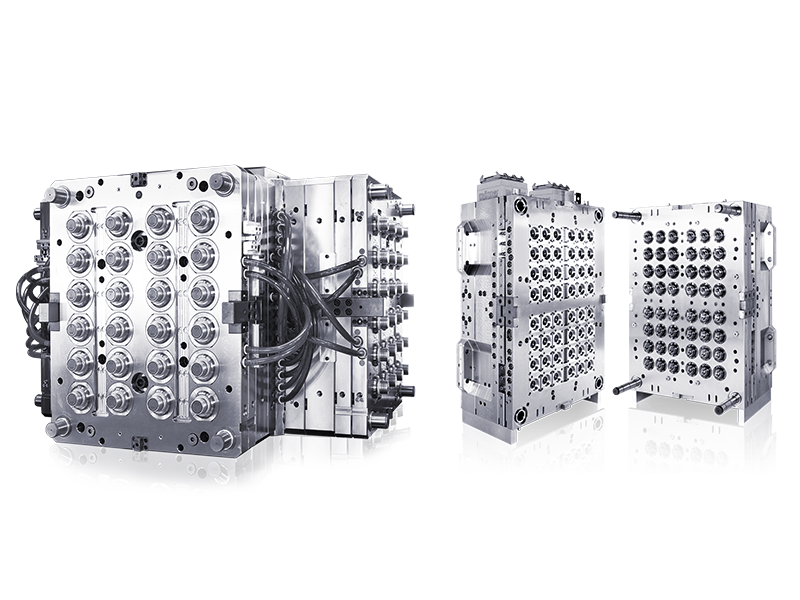

For Multicavity and Large Part Applications Hot Runner Systems

For Multicavity and Large Part Applications Hot Runner Systems -

For Better Results Controls

For Better Results Controls

Exzellenz durch Spezialisten

Durch die enge Zusammenarbeit von Männer, Foboha, Synventive, Thermoplay, Priamus und Gammaflux entstehen integrierte Lösungen, die den Weg für das adaptive Spritzgießen ebnen – intelligent, vernetzt und zukunftsorientiert.

Excellence through specialists

The close collaboration between Männer, Foboha, Synventive, Thermoplay, Priamus, and Gammaflux enables integrated solutions that pave the way for adaptive injection molding – intelligent, connected, and future-oriented.

-

For Multicavity and High Cavity Applications High Precision Molds

For Multicavity and High Cavity Applications High Precision Molds

Hot Runner SystemsMänner specializes in the development and production of high-precision injection molds and hot runner systems.

These durable, high-cavity systems are ideal for large-scale production of precision plastic parts with long product life cycles – especially in the medical and pharmaceutical industries.

As the inventor of the cylindrical valve gate – widely recognized as the best hot runner solution for flawless gate quality – and with extensive validation expertise, Männer is a trusted partner for manufacturing high-precision plastic components, such as medical disposables or pharmaceutical devices.

All components meet the highest standards for dimensional accuracy and reproducibility – critical prerequisites for fully automated assembly, regardless of the global production location.

Molds and hot runner systems from a single source – perfectly matched for maximum precision and process reliability.

-

For Multicavity and High Cavity Applications High Performance Molds

For Multicavity and High Cavity Applications High Performance MoldsFoboha stands for innovative solutions and uncompromising quality in mold making.

As a pioneer in the development of complex mold technologies, Foboha has earned a global reputation – particularly through the invention and continuous advancement of cube technology, which enhances the production of plastic parts both technically and economically.

This technology enables shorter cycle times, significantly increased output, and the integration of complex processes directly within the mold.

Foboha is therefore especially in demand in industries where maximum efficiency, flexibility, and part variety are essential – such as the packaging and consumer goods sectors.

-

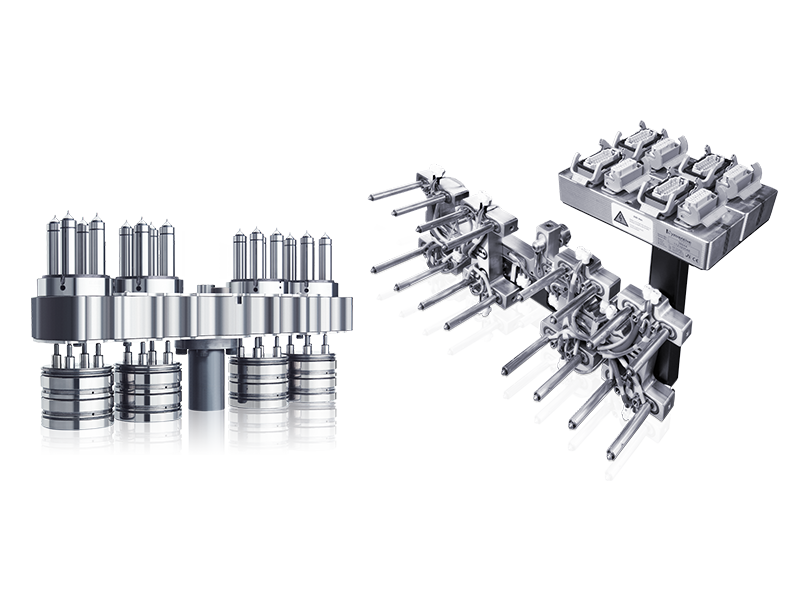

For Automotive & Mobility Hot Runners and Flow Control Technology

For Automotive & Mobility Hot Runners and Flow Control TechnologySynventive delivers advanced hot runner and flow control technology for the production of large plastic parts.

As a long-standing and trusted partner of the automotive and mobility sectors, Synventive specializes in sequential injection molding – with a strong focus on surface quality, scrap reduction, and maximum production efficiency.

Whether it’s sophisticated lighting components or durable battery covers for e-mobility, Synventive enables high-performance solutions for forward-looking automotive applications.

-

For Multicavity Applications Hot Runner Systems

For Multicavity Applications Hot Runner SystemsThermoplay offers smart, straightforward hot runner technology – ideal for applications with medium cavity counts.

Thanks to efficient standardization and practical design, Thermoplay provides technically reliable hot runner systems and nozzle-side mold halves with an especially attractive price-performance ratio.

Whether for side gating, multicolor parts, or simple special requirements – Thermoplay delivers dependable technology that works without complexity: flexible, proven, and economical.

Thermoplay is particularly well suited for efficient series production in packaging, consumer goods, transportation, and electronics – offering practical solutions that meet real-world demands.

-

To Ensure Maximum Process Stability Process Control

To Ensure Maximum Process Stability Process ControlPriamus develops solutions for reliable monitoring of injection molding processes – up to fully automated closed-loop control systems.

The product range includes cavity pressure and temperature sensors, digital amplifiers and interfaces, as well as complete software systems for quality assurance in injection molding.

Priamus systems are designed to detect and reject defective parts, automatically optimize the process, and ensure consistently high quality throughout the entire production run.

This enables significant cost savings – while ensuring maximum process reliability.

-

For Better Results Temperature & Sequential Control

For Better Results Temperature & Sequential ControlGammaflux specializes in temperature and sequential control for modern hot runner systems.

Precise temperature management is critical for optimal part quality, minimal scrap rates, and economic efficiency.Gammaflux’s high-precision, user-friendly control technology supports both advanced temperature regulation and sequential gating in complex injection molding processes.

With intelligent monitoring, fast response times, and flexible control options, Gammaflux makes a significant contribution to consistent product quality and stable processes – across industries and applications worldwide.

We speak your industry’s language

With deep, specialized expertise in automotive & mobility, medical/pharma, packaging FMCG, and electronics, we understand your challenges and goals.

-

Medical / Pharma

Devices

Autoinjectors

Insulin Pens

Insulin Pumps

InhalersDisposables

Dialysis Components

IVD (In Vitro Diagnostics)

Pipette Tips

Clinical Consumables -

Packaging FMCG

Thinwall Packagings

Container

Caps & Closures

Personal Care -

Automotive & Mobility

ExteriorInteriorUnder Hood

E-Cars

Lighting

Transport Systems -

Electronics &

Technical PartsIndustrial E&E

Consumer E&EPower Tools

Domestic Appliances

White WareTechnical Parts

Global Presence for Global Players

![]()

7

Production

Locations

![]()

>60

Sales & Service

Locations

![]()

2000

Employees

Worldwide

![]()

>700

Patents &

Trademarks

»Our Contribution to Loyal and Satisfied Customers«

Marcello Vendemiati

President

Molding Solutions

Insights in Our Facilities

-

Bahlingen, Germany

Bahlingen, Germany -

Haslach, Germany

Haslach, Germany -

Lawrenceville, USA

Lawrenceville, USA -

Pont-Saint-Martin, Italy

Pont-Saint-Martin, Italy -

Suzhou, China

Suzhou, China -

5-Axis Milling

5-Axis Milling -

Suzhou, China

Suzhou, China -

Fluidized bed cleaning

Fluidized bed cleaning -

Hot runner assembly

Hot runner assembly -

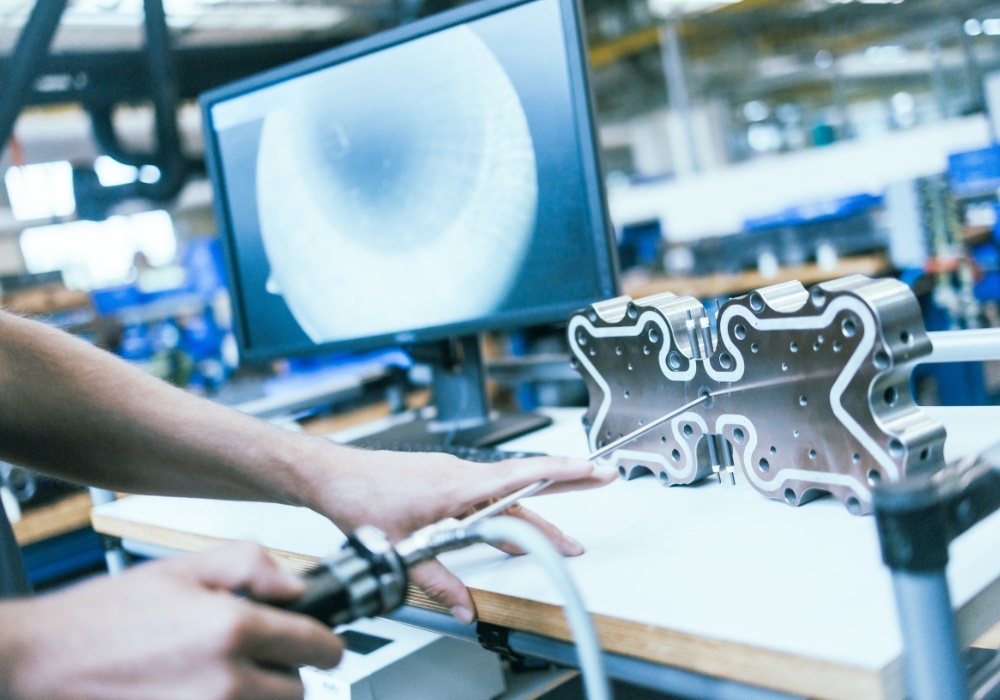

Hot Runner Endoscopy

Hot Runner Endoscopy -

Bahlingen, Germany

Bahlingen, Germany -

Optical Inspection

Optical Inspection -

Hot runner cleaning in an ultrasonic bath

Hot runner cleaning in an ultrasonic bath -

EDM

EDM -

Automation of HSC milling

Automation of HSC milling -

HSC milling robot

HSC milling robot -

Mold Assembly

Mold Assembly -

Protomold - Mold Optimization

Protomold - Mold Optimization -

Tool rotator

Tool rotator -

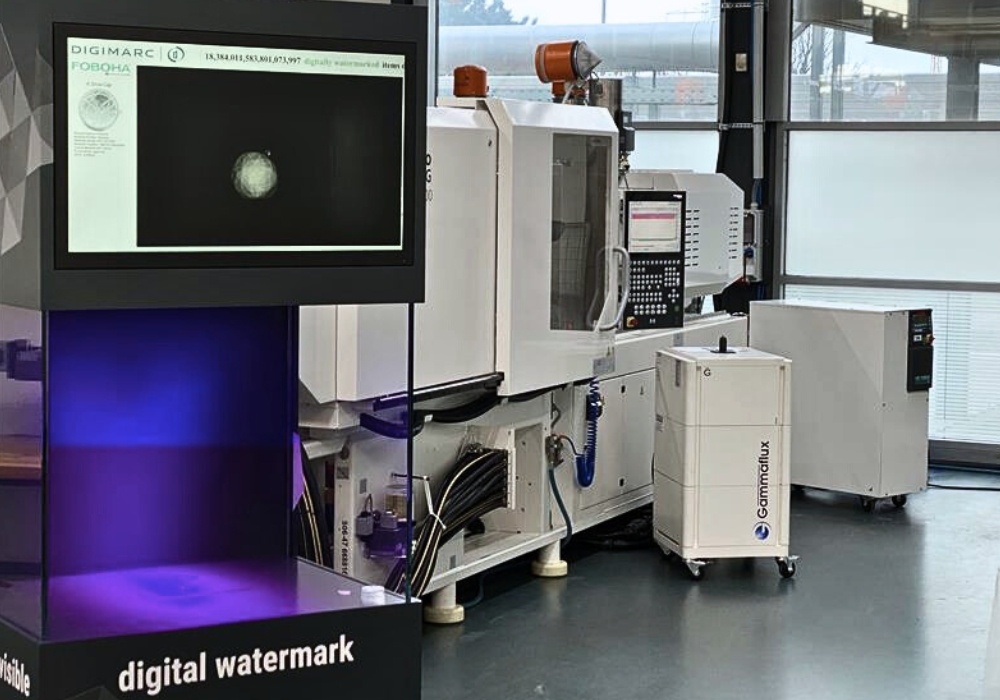

Digital Watermark Test Station

Digital Watermark Test Station -

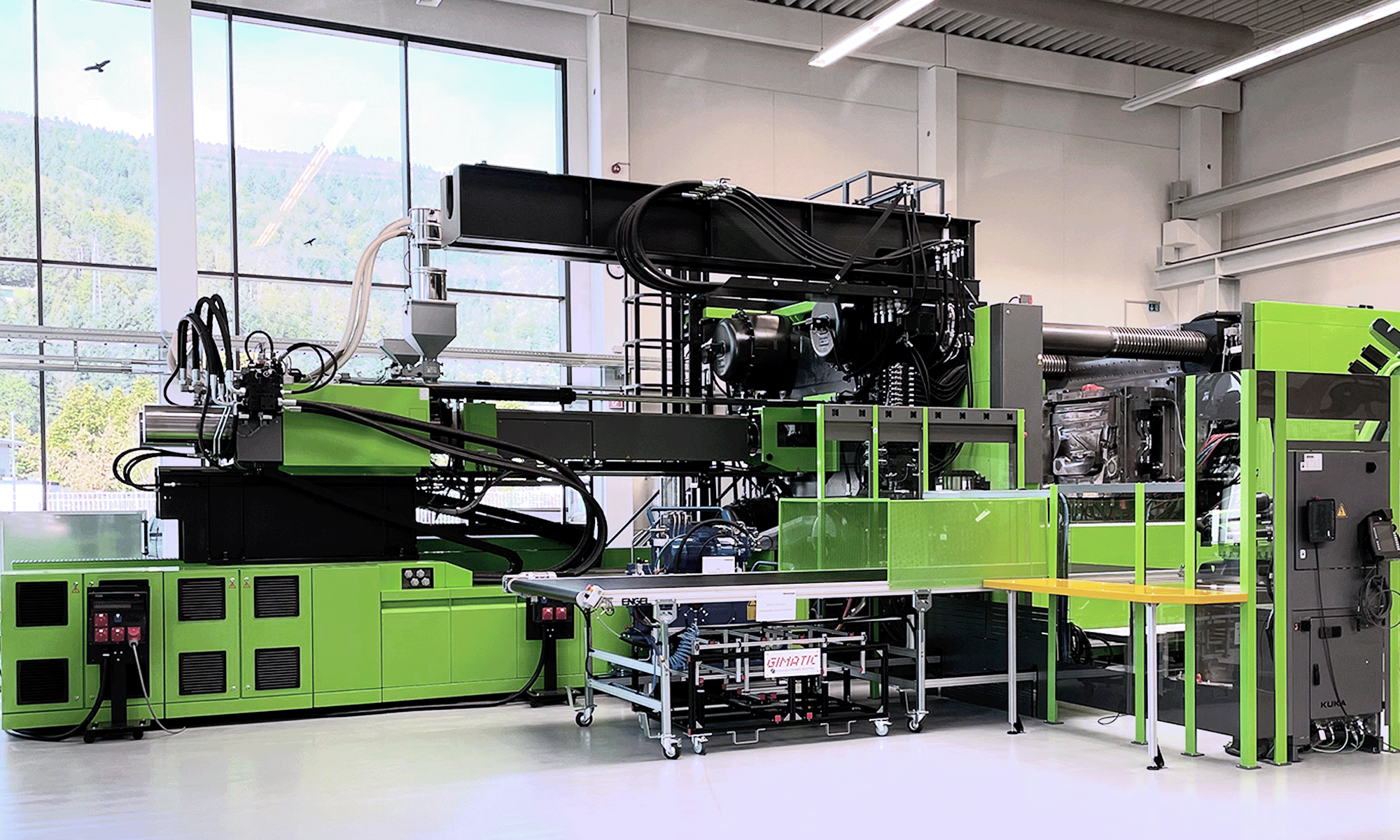

Tech Center Haslach, Germany

Tech Center Haslach, Germany -

Tech Center Pont St. Martin, Italy

Tech Center Pont St. Martin, Italy -

Bahlingen, Germany

Bahlingen, Germany