%20(1000%20x%201000%20px)%203.jpg)

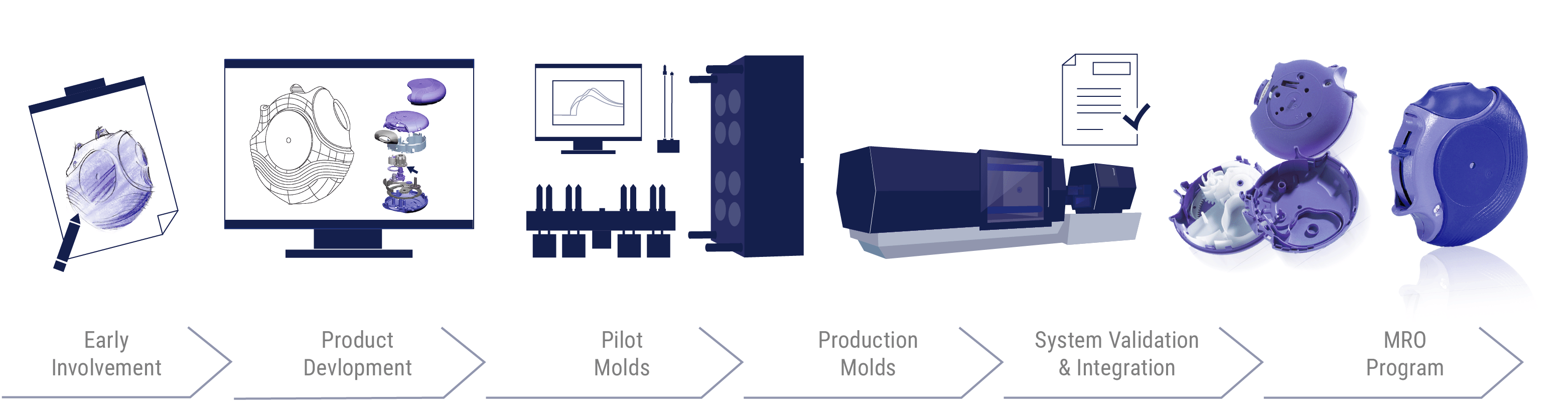

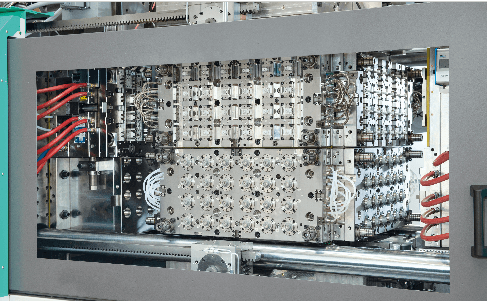

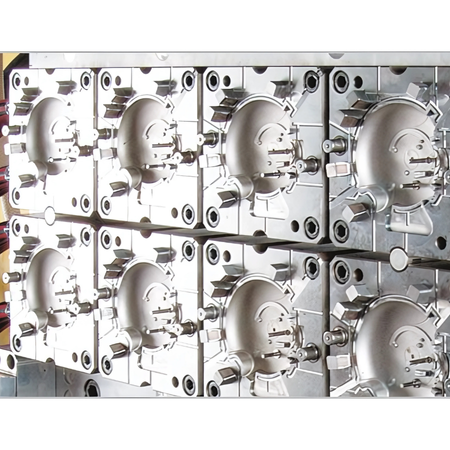

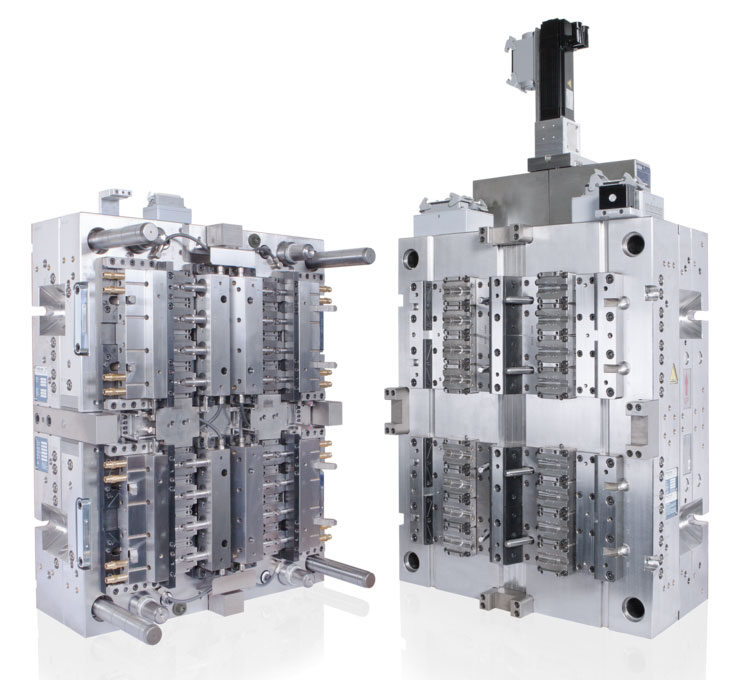

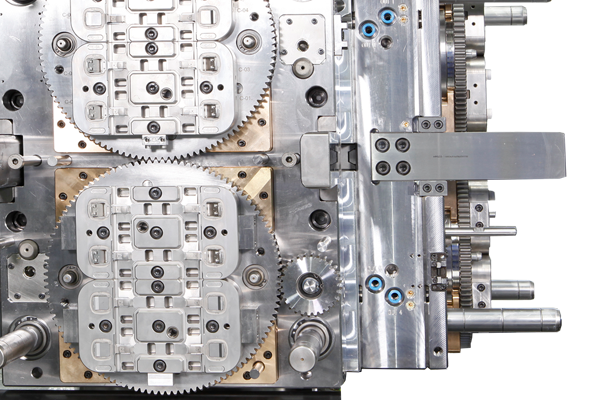

Stack Molds

Männer & Foboha

Our Molds combine precision engineering with advanced manufacturing technology to deliver superior performance, cycle after cycle.

Designed for reliability, efficiency, and endurance, they help manufacturers achieve lower production costs, higher output, and uncompromising part quality.

Have a question or idea? We’d love to hear from you.

Global Resources

Testing, qualification, and material tests take place in our Tech Centers. We operate more than 40 injection molding machines worldwide, along with equipment for optical and tactile inspection of plastic parts, thermal imaging, moisture testing, high-speed cameras, and flow meters. For our customers, we install complete custom production cells in dedicated areas with their own office units.

Unmatched in Efficiency

Particularly for complex multi-component applications requiring assembly, cycle time can be drastically reduced as processes like injection, cooling, assembly, and part removal can occur simultaneously.

Shifting assembly processes into the mold also reduces the need for assembly lines, significantly minimizing space requirements. Utilizing both sides of the cube doubles the cavity count, increasing production capacity.

Pharmaceutical Devices

Thanks to global resources and availability, we are capable of supporting even extensive mold projects. An example of large-scale mold projects includes inhalers, insulin pens, or auto-injectors, the so-called "pharmaceutical devices". These assemblies consist of up to 15 individual parts produced at various locations around the world and, if necessary, fully assembled automatically.

We can produce all the molds required for each component and ensure the dimensional accuracy necessary for fully automated further processing.

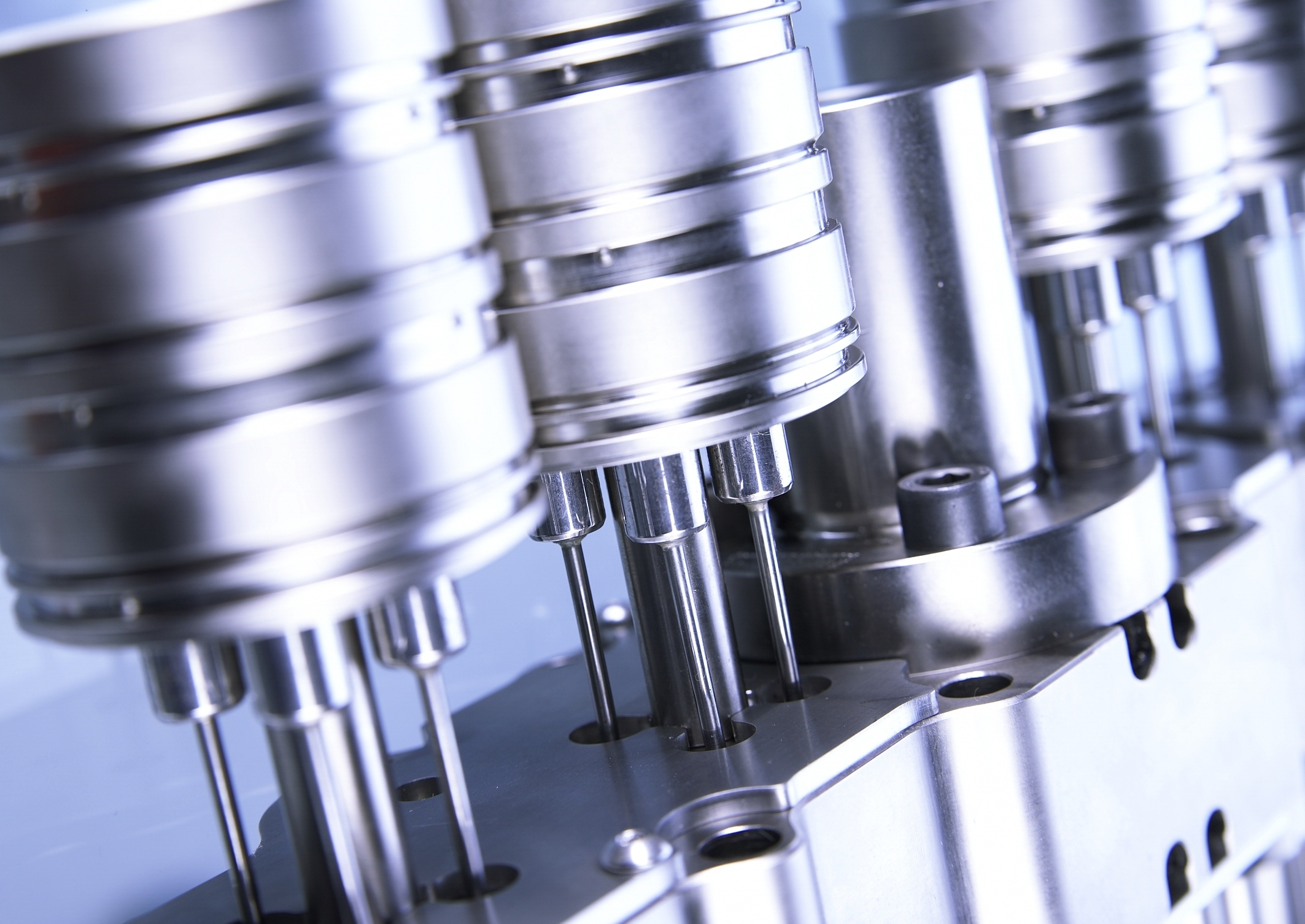

Stable and Robust Molds

Durable by design and backed by decades of moldmaking expertise, our molds deliver exceptional longevity and consistent performance.

Global Standards

We have decades of experience in qualification up to SAT Ready, qualifying according to customer-specific standards or the Molding Solutions Standard, developed based on Scientific Molding. Regardless of whether we qualify in the APAC, EMEA, or American region, we always apply the same qualification standards.

Manufacturing, Sales and Service

With 8 state-of-the-art production facilities and more than 60 service and sales locations worldwide, we ensure proximity, fast response times, and reliable support — wherever you need us.

Packaging Applications

Designed for speed to market, our packaging molds combine optimized temperature management with a high-performance in-house hot runner system. The result: ultra-short cycle times, outstanding efficiency, and the reliability to scale your production faster.

.webp?width=908&height=547&name=ms-turnkey-solutions-250x150%20(1).webp)

Isn't it simpler and more cost-effective to have just one responsible partner for everything that happens "between the platens"?

A hot runner system perfectly tailored to your mold, the right control tools to make your mold smarter and even more efficient, and no finger-pointing if something ever goes wrong. Because you have only one accountable point of contact.

Often, it’s just small product adjustments that make series production more efficient and productive. Involve us in your planning at an early stage! Our systematic approach is our responsibility to ensure that the product ideas of our customers are brought to fruition reliably and profitably. Our engineering experts assist you every step of the way – from the conception stage to the delivery of comprehensive product solutions.

.png)

From targeted repairs to full mold refurbishment – our After Sales Services ensure maximum uptime and performance. Planned refurbishment helps avoid unexpected failures, extend mold lifespan, and significantly reduce long-term costs.

Whether you need quick service, tailored maintenance, or a complete overhaul: you get expert support, when and how you need it. Proactive. Reliable. Mold-specific.

The Cube Mold Technology is a breakthrough in high-performance injection molding. Unlike conventional systems, the cube design uses a rotating core that indexes in 90° steps, allowing multiple production processes to run in parallel. While one side of the cube is being injected, another side is cooling, and yet another is ejecting finished parts.

This systematic overlap of processes eliminates wasted time between steps, delivering unmatched efficiency and productivity.

Our high-performance hot runner systems are designed to deliver maximum efficiency, consistent product quality, and long-lasting reliability enabling manufacturers worldwide to optimize processes and reduce costs.

.jpg)

Medical Day 2025 brought together brilliant minds, inspiring speakers, and a passionate community dedicated to shaping the future of healthcare. From thought-provoking talks to lively networking moments, the day was filled with energy and ideas. Here’s a look back at some of the highlights.

Whether your mold requires only minor adjustments or a full mechanical and functional overhaul: we offer a flexible range of refurbishment solutions to match your goals, timeline, and budget. All packages are carried out by experienced tooling experts using OEM-level standards and documentation. Planned refurbishment reduces unexpected downtime, lowers total cost of ownership, and keeps your production running efficiently.

Our Light Package focuses on essential components to restore reliable performance with minimal downtime:

Full refurbishment of the hot runner system

Replacement of guiding and centering elements for FH & MH (AS & DS)

Warranty renewal of the hot runner system in accordance with Otto Männer GmbH’s general terms and conditions

This package is ideal for molds still in good condition that require targeted maintenance to ensure consistent part quality and continued process stability.

Our most comprehensive package restores your mold to peak performance – ideal for extending lifecycle and maximizing output reliability:

Complete replacement of cavity stacks

New guiding and centering elements

Replacement of all wear and tear parts

Full cleaning and inspection of the entire mold

Final Operational Test (FOT) to validate performance

Warranty renewal with 50% of the original new mold conditions – minimum 1 million cycles guaranteed

This package is recommended when a mold shows extensive wear or reduced precision. It offers a cost-efficient alternative to new mold investment, with high functional reliability.

.png)

Tailored refurbishment after a comprehensive mold assessment – based on the exact condition and requirements of your mold.

On-site assessment by our experts

Customized quotation based on actual wear and condition

Refurbishment performed at the MS mold plant, using OEM standards

Final Operational Test (FOT) ensures mold readiness

Warranty renewal after full refurbishment with 50% of the original warranty conditions – minimum 1 million cycles

Cost transparency & value-added:

Refurbishment > €100k → 50% reimbursement of the assessment costs

Refurbishment > €200k → 75% reimbursement of the assessment costs

Optional add-ons:

Spare parts packages (mold / hot runner)

Stand-alone repairs of damaged components (if feasible)

Modifications to meet new production or product requirements

This package is ideal for complex, high-value molds where a detailed condition-based approach ensures maximum return on investment.

Planned hot runner maintenance can reduce downtime by up to 70%.

Always Ready, Always Reliable: A spare parts agreement with Männer or Foboha ensures that essential components are always available to keep your molds running smoothly. By securing predefined parts in advance, you minimize downtime and increase efficiency.

Your benefits at a glance:

Rapid availability

Immediate access to critical spare parts – less unplanned downtime, better service performance.

Cost efficiency

Attractive long-term conditions and pricing through fixed contracts.

Planning reliability

Simplified scheduling of maintenance and repairs with assured parts supply.

Lower administrative effort

Reduce time and resources needed for sourcing and procurement

Vertical: {{ product.vertical }}

Material: {{ product.application.a_material }}

Part Weight: {{ product.application.a_part_weight }}

Shot Weight: {{ product.application.a_shot_weight }}

Wall Thickness: {{ product.application.a_wall_thickness }}

Brand: {{ product.hot_runner.h_brand }}

Nozzles: {{ product.hot_runner.h_nozzles }}

Actuators: {{ product.hot_runner.h_actuators }}

System: {{ product.hot_runner.h_system }}

Drops: {{ product.hot_runner.h_drops }}

Cavities: {{ product.hot_runner.h_cavities }}

Notes: {{ product.hot_runner.h_notes }}

Brand: {{ product.mold.m_brand }}

Technology: {{ product.mold.m_technology }}

Cavities: {{ product.mold.m_cavities }}

Note: {{ product.mold.m_note }}