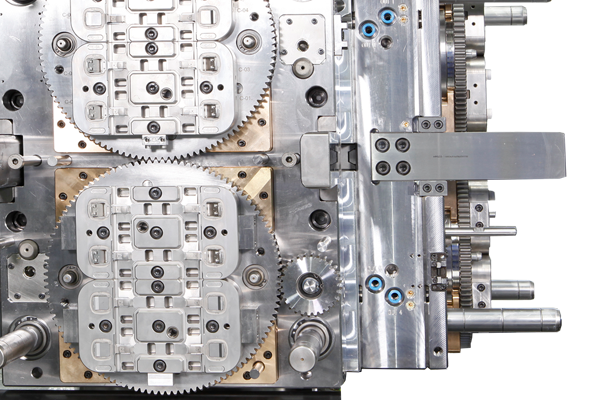

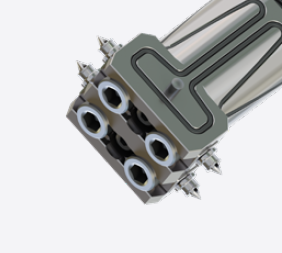

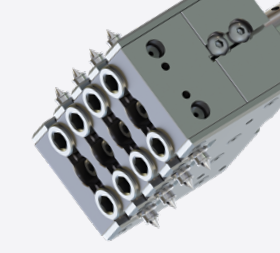

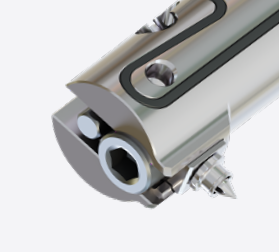

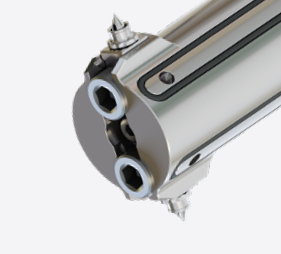

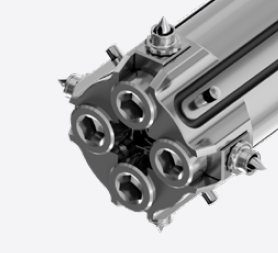

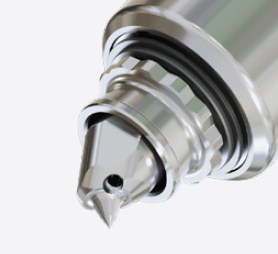

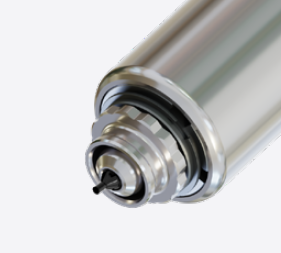

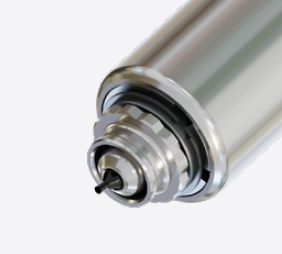

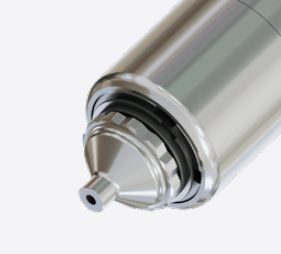

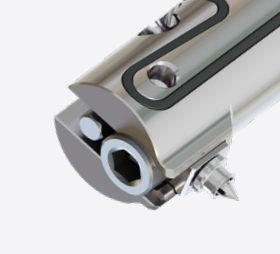

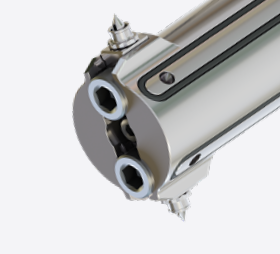

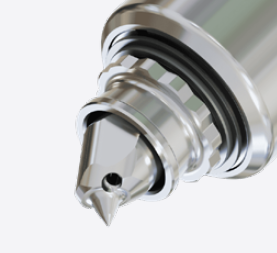

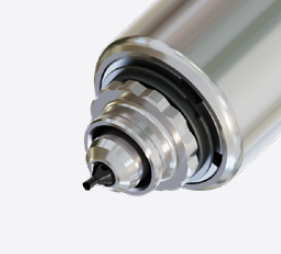

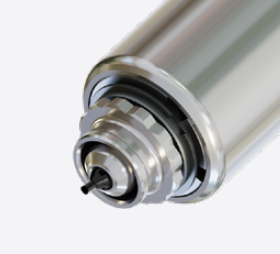

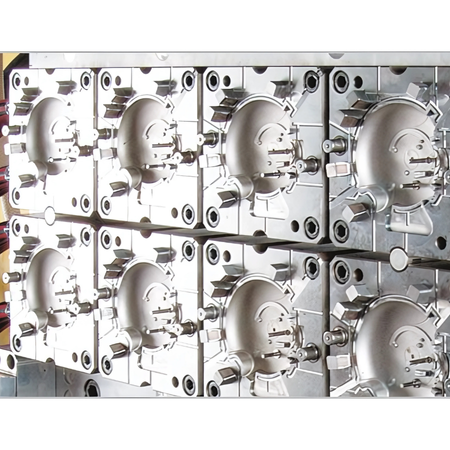

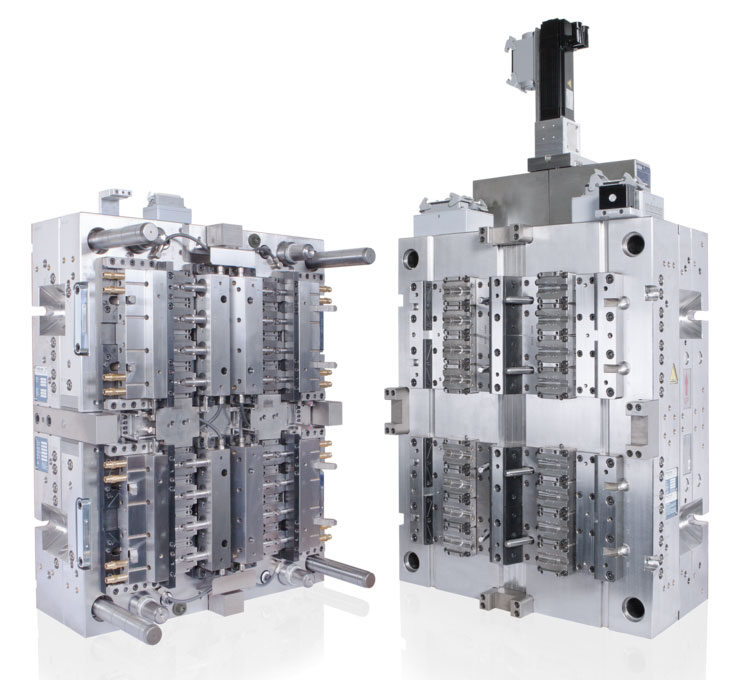

Signature Line

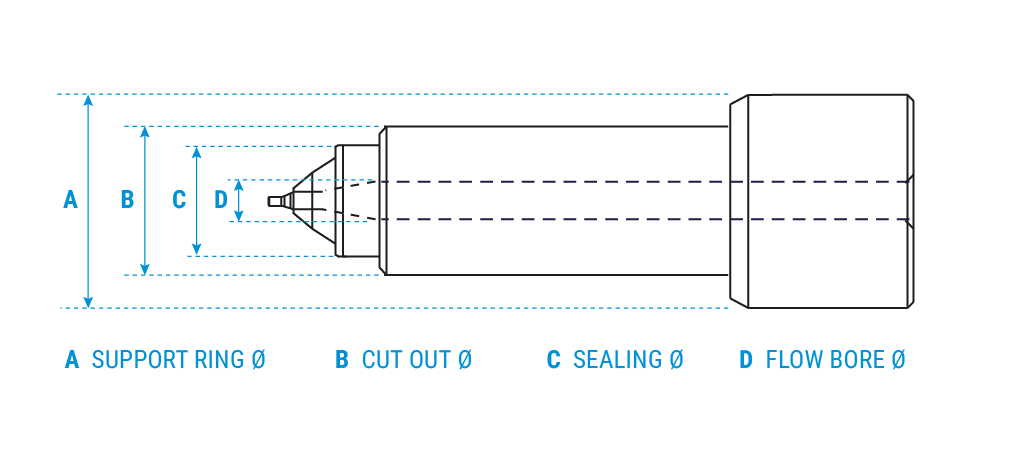

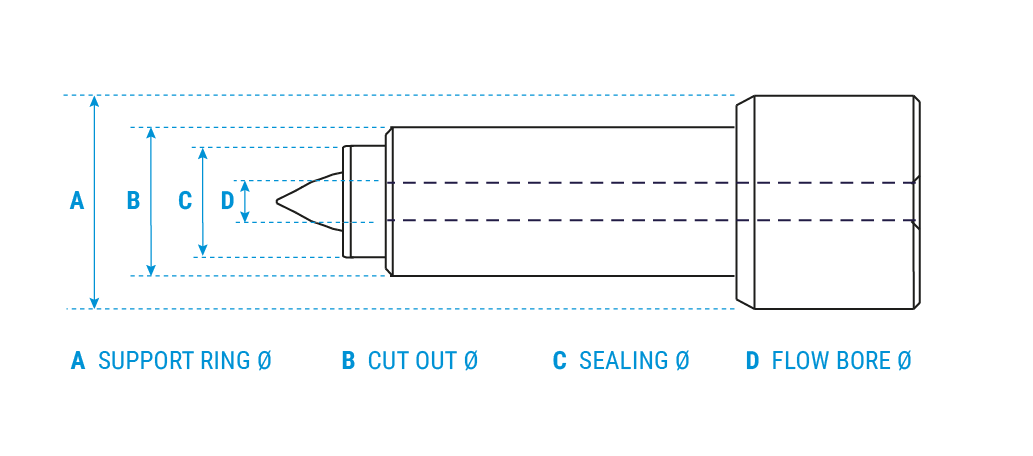

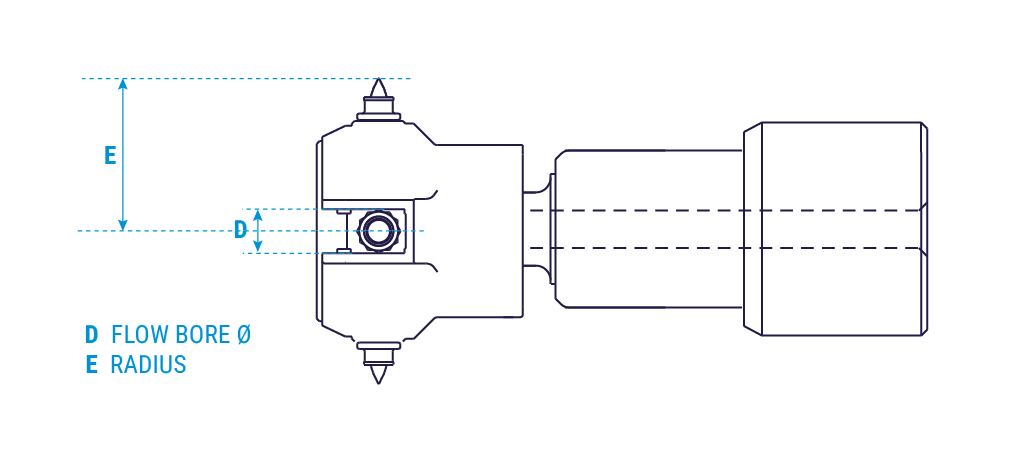

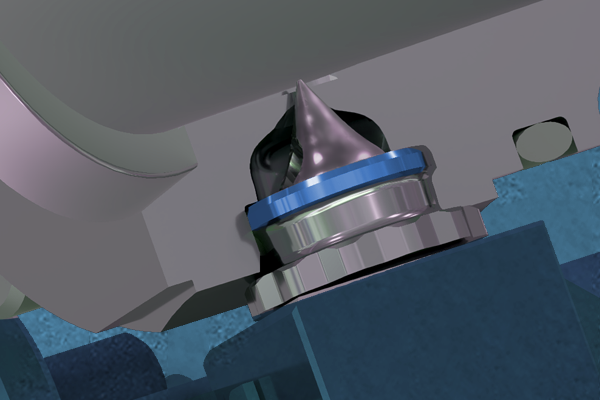

featuring the Original Männer Valve Gate Technology.

The Signature Line with the Original Männer Cylindrical Valve Gate Technology provides impeccable surface quality, part-to-part consistency, and process reliability. All hot runner systems are tailored and designed to meet the specific needs of our customers.

.png)

.png)

.png)

.jpg)

.png)