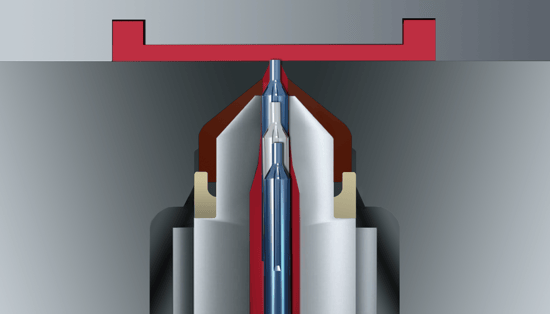

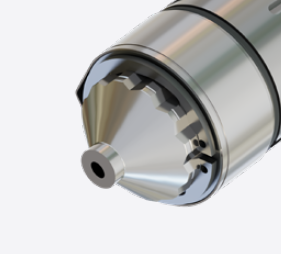

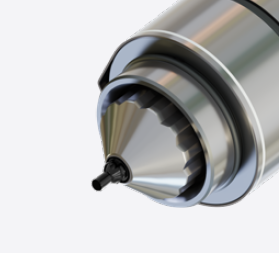

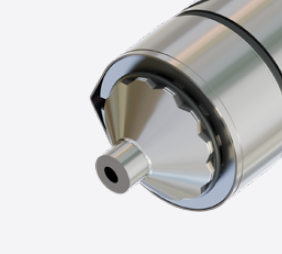

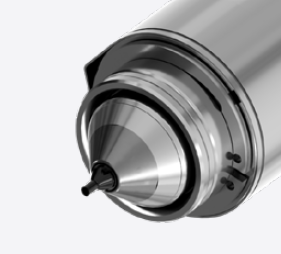

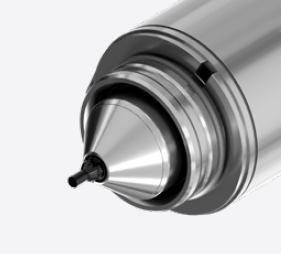

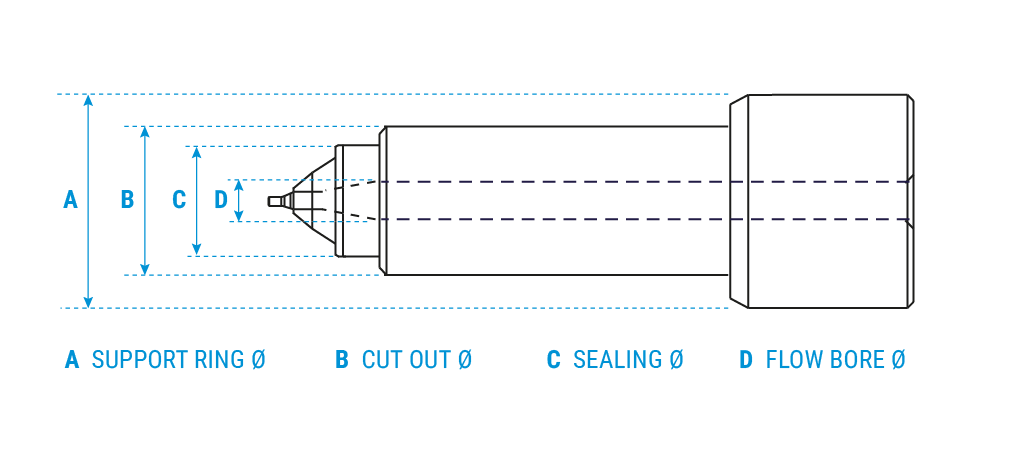

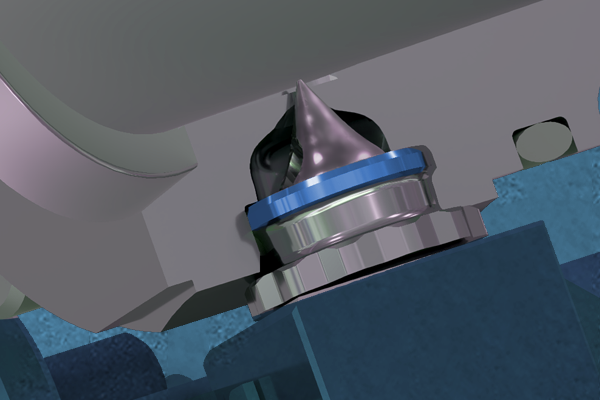

Precentered Cylindrical Valve Gate

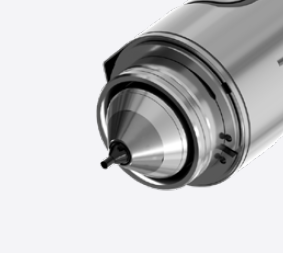

During the closing movement, the valve pin is first precentered by an angled guide area and then positioned perfectly in the gate orifice by means of a cylindrical guide. Nozzle and valve pin are designed to provide maximum performance and extreme durability.

- Superior gate quality

- Large gate cross section

- Minimal pressure drop

- Low shear rates

- Extreme durability wear and maintenance

- Defined opening and closing of the gate orifice

- Processing of demanding materials with narrow processing windows

- Short cycle times

- Individual heating control

- Clean room compatible

.png?width=1280&height=400&name=Sealing%20(1).png)

.png)

.png)

.jpg)

.png)