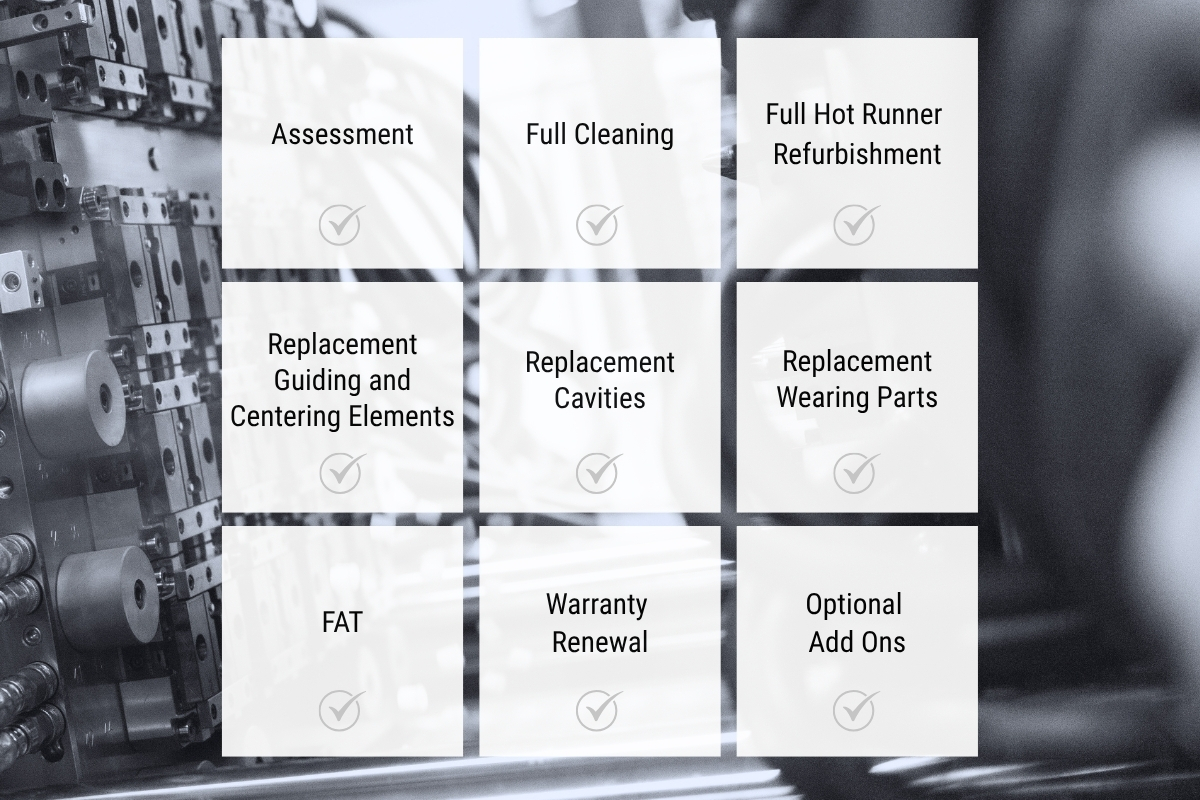

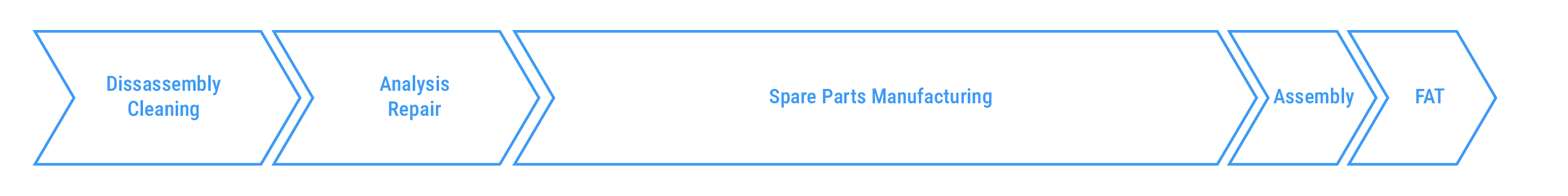

We offer three smart refurbishment options to suit your tool’s condition, production demands, and budget:

-

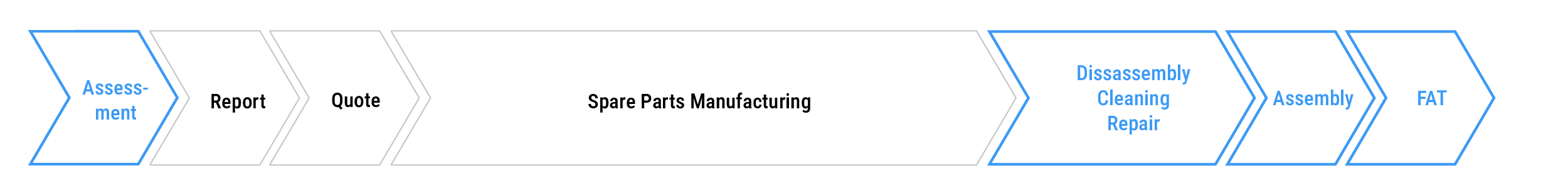

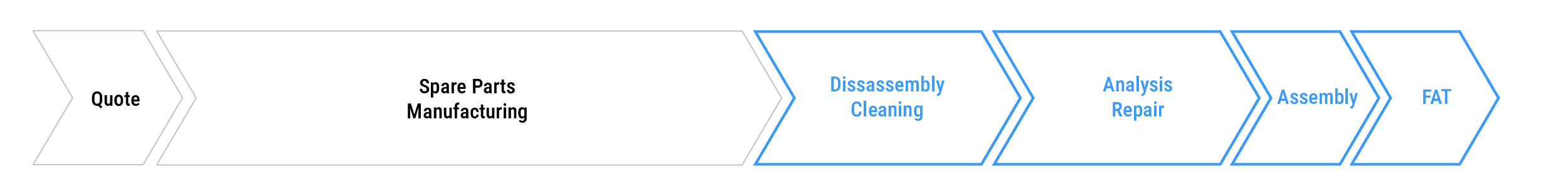

Light Package – A lean service option for tools in good condition, including core modules like assessment, cleaning, and selected part replacements.

-

Full Package – A comprehensive overhaul including hot runner refurbishment, cavity replacement, warranty renewal, and factory acceptance test (FAT).

-

Customized Package – Fully modular: select only the services you need – from single-module maintenance to advanced performance upgrades.

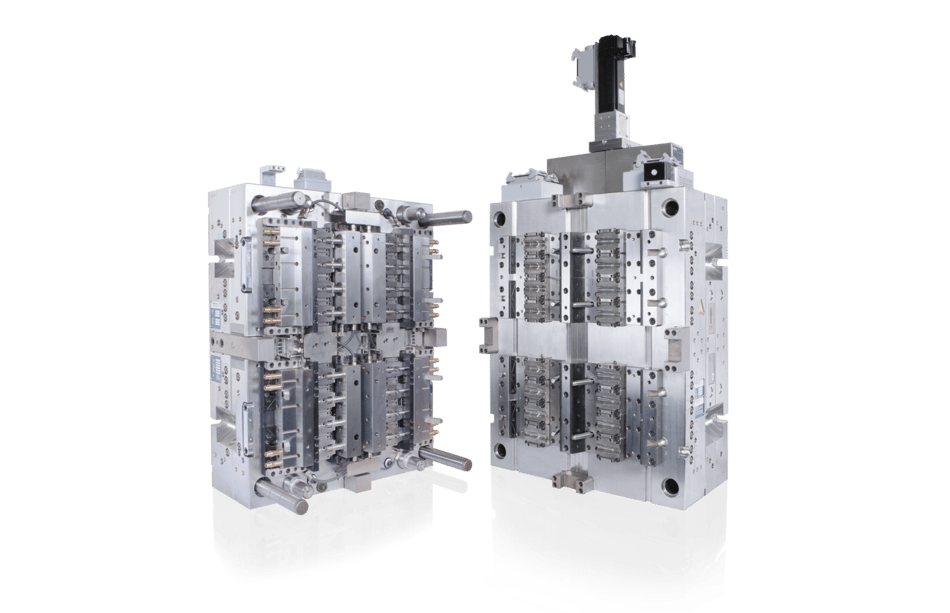

For cube molds, we offer a dedicated refurbishment program tailored to their complexity and high-performance requirements – ensuring precision, uptime, and reliability at scale.

Every package is built on our modular service structure – combining speed, quality, and long-term value.

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)