Precision is more than a standard – it’s our identity.

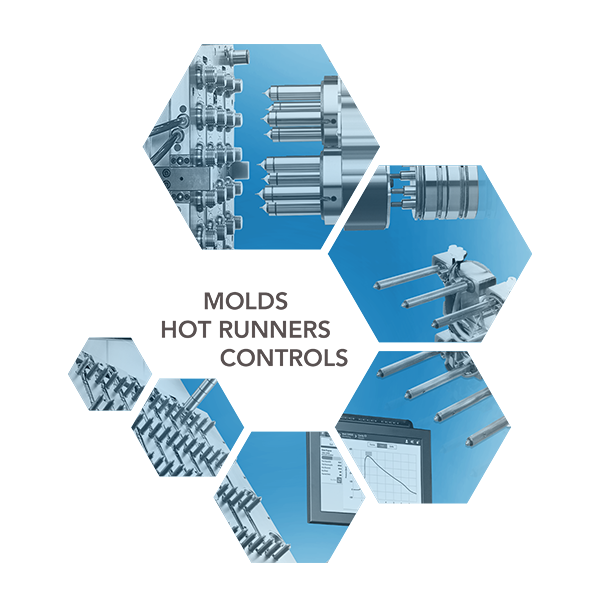

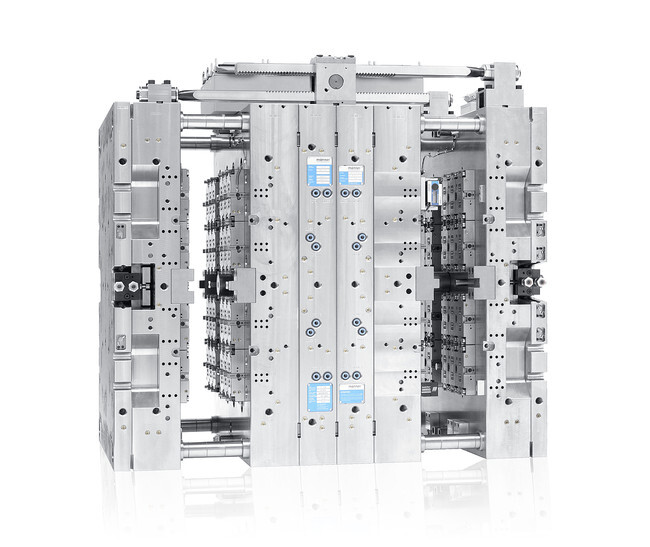

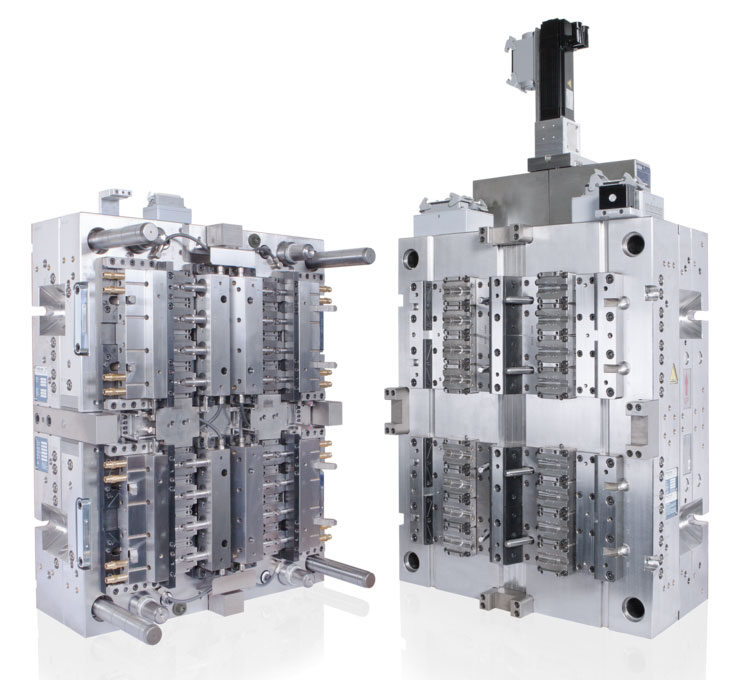

For over five decades, we’ve been a trusted partner for manufacturers worldwide, delivering hot runner systems and injection molding tools that set the benchmark for efficiency, durability, and process reliability.

Our German-engineered solutions are designed to meet the highest demands in automotive, medical technology, packaging, and consumer goods industries. With cutting-edge manufacturing technology, a deep understanding of polymer processing, and a relentless focus on innovation, Männer ensures your production runs faster, cleaner, and more cost-effectively.

-2.jpg)

.png)

.jpg)

.png)