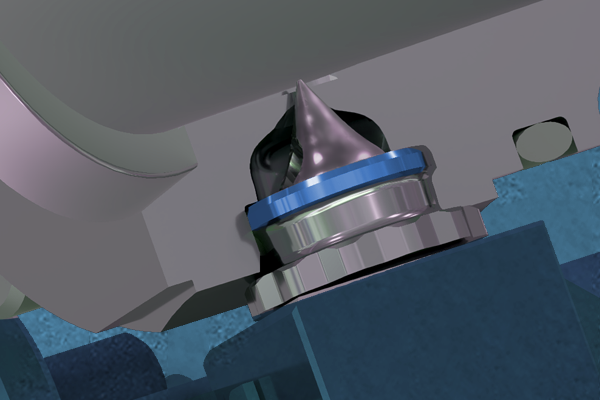

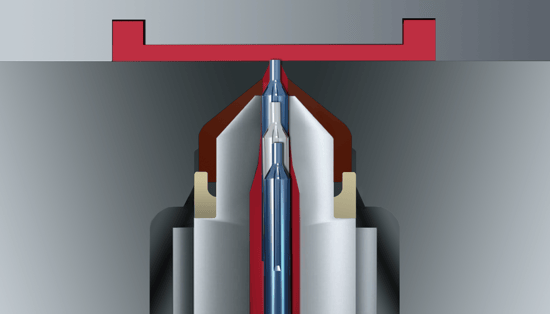

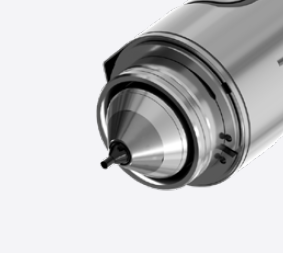

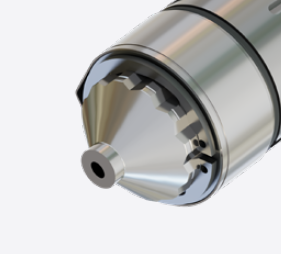

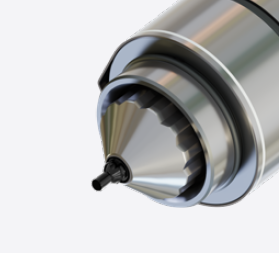

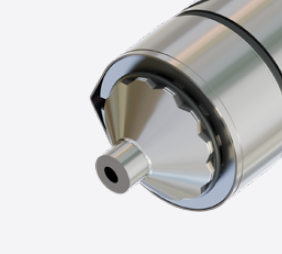

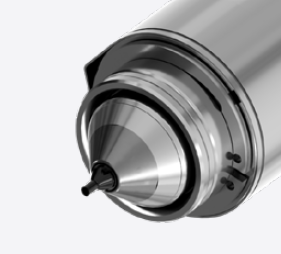

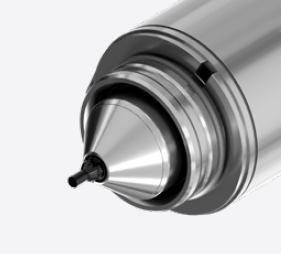

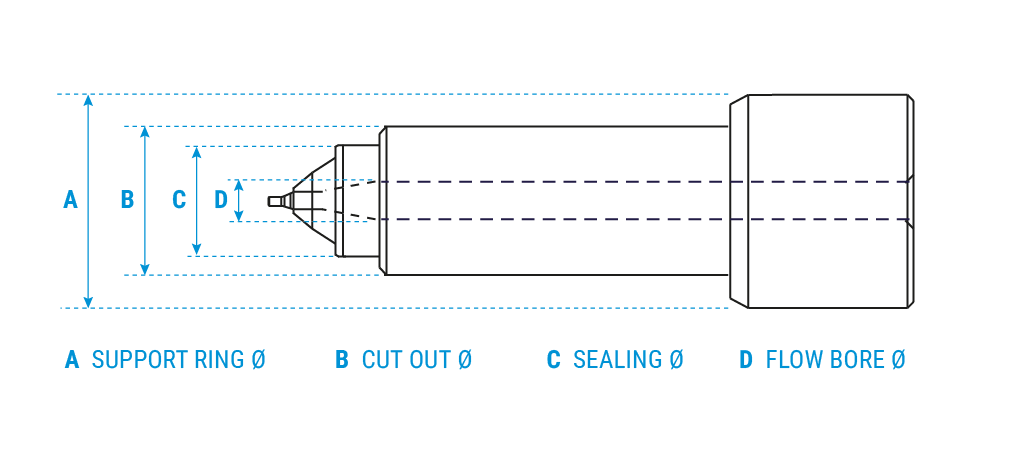

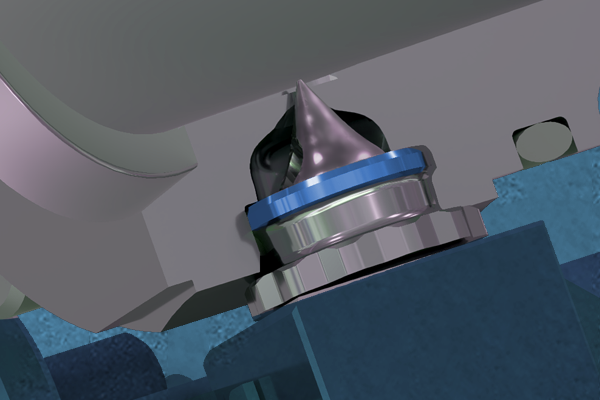

Spillo cilindrico precentrato

Durante il movimento di chiusura, lo spillo dell'otturatore viene prima precentrato da una guida angolata e poi posizionato perfettamente nel foro del gate mediante una guida cilindrica. Ugello e spillo dell'otturatore sono progettati per offrire massime prestazioni ed estrema durata.

- Qualità superiore del gate

- Ampia sezione trasversale del gate

- Minima perdita di pressione

- Ridotto stress da taglio

- Estrema durata, resistenza all’usura e ridotta manutenzione

- Apertura e chiusura definite dell’orifizio del gate

- Lavorazione di materiali impegnativi con finestre di processo ridotte

- Tempi di ciclo brevi

- Controllo di riscaldamento individuale

- Compatibile con clean room

.png?width=1280&height=400&name=Sealing%20(1).png)

.png)

.png)

.png)

.jpg)

.png)