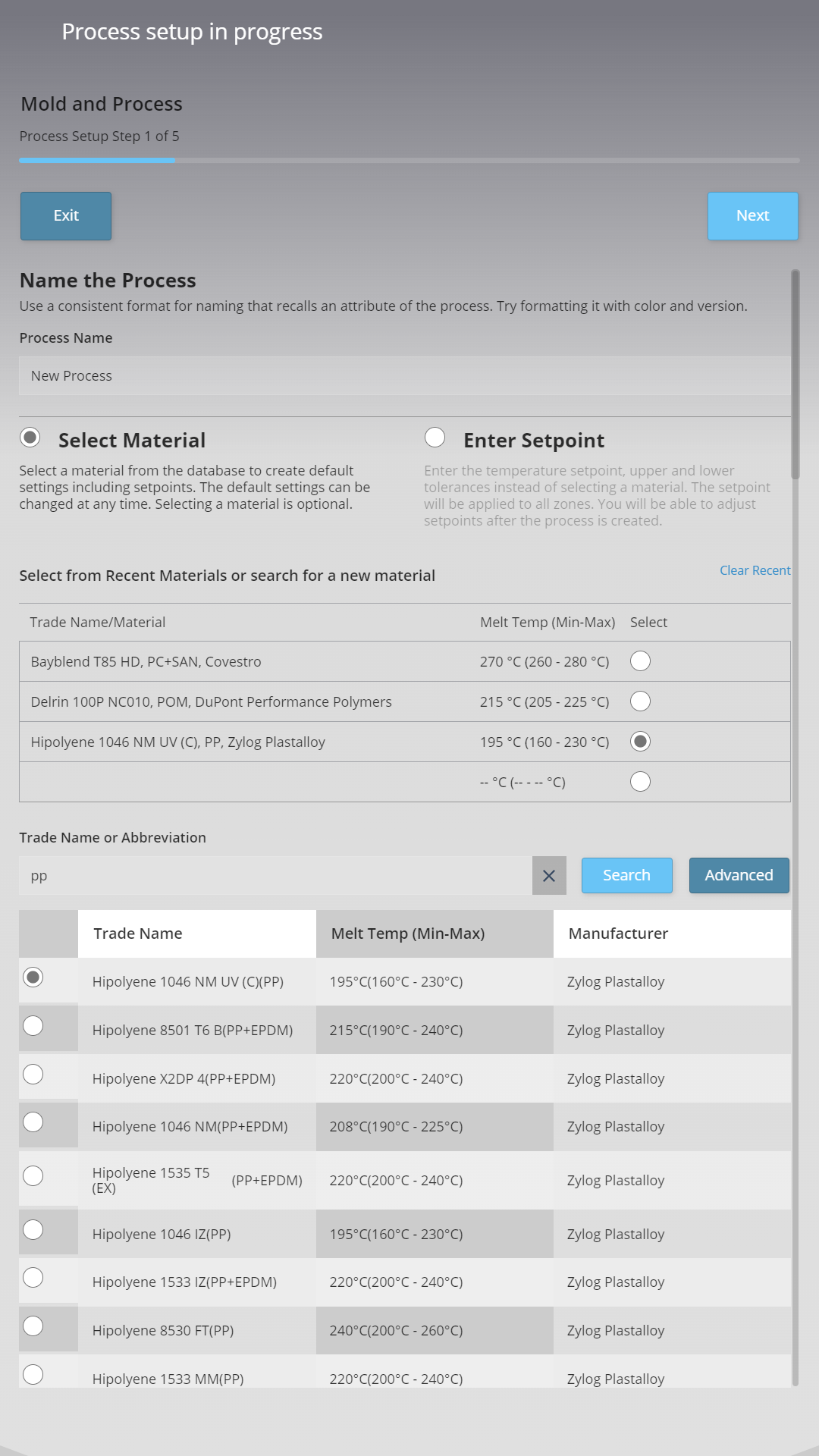

Easy Set Up with Mold Wizzard

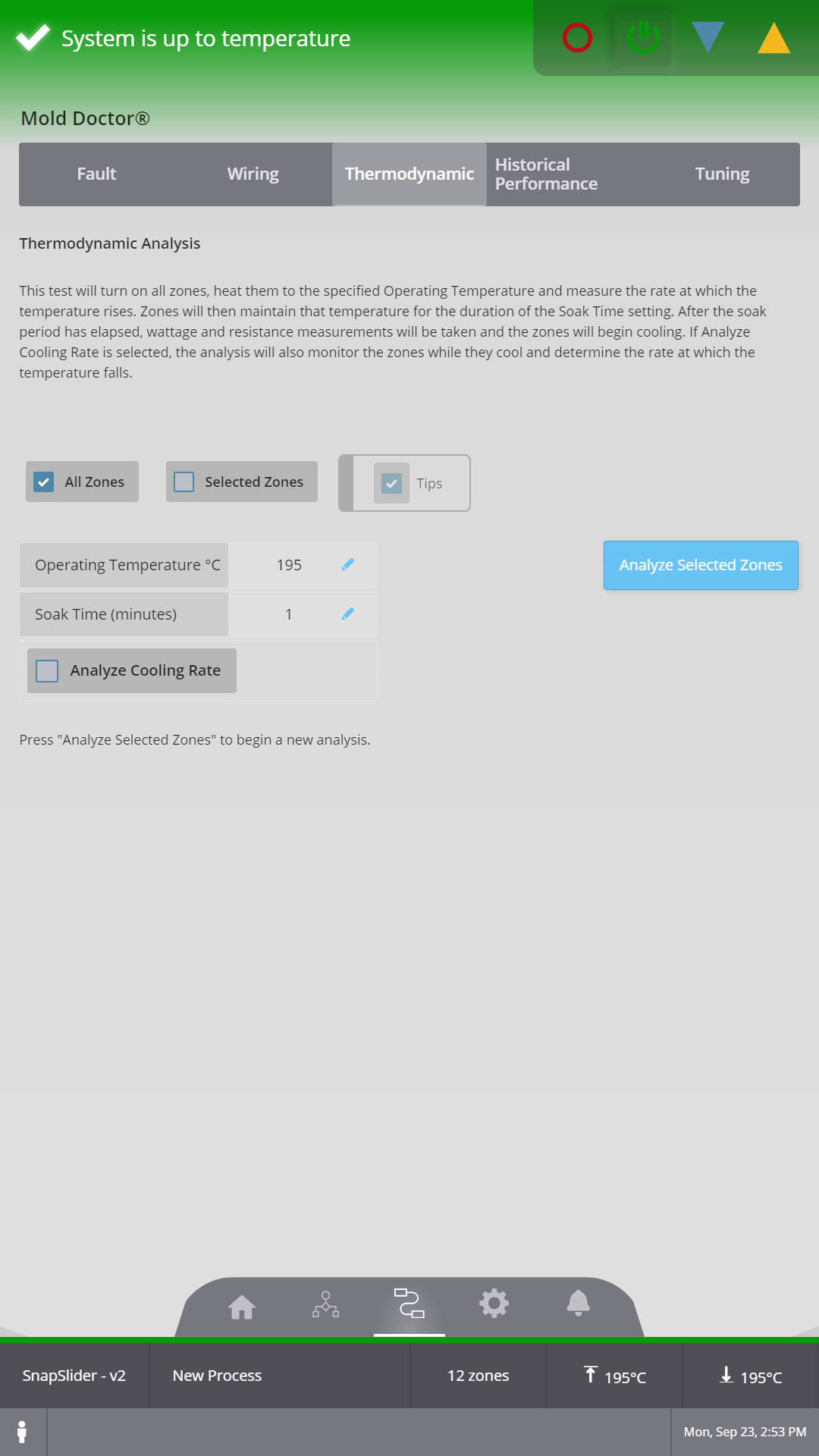

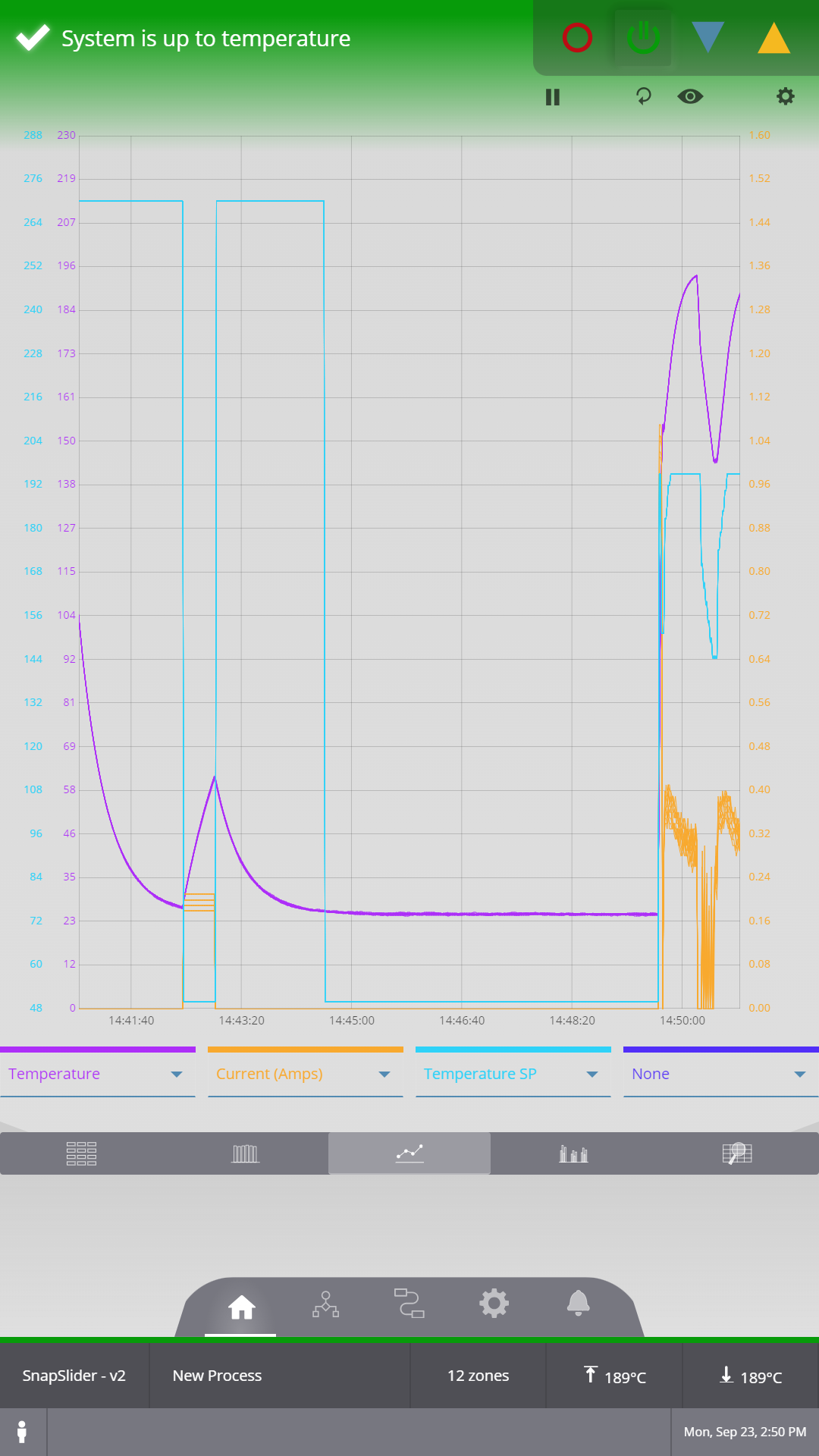

The G25 is built for simplicity. It is designed to operate seamlessly based on industry best practices. The New Mold Wizzard effortlessly assists users through each stage: starting from configuring zones and settings to advanced tasks such as mold startup and heating.

- Configure Mold and Layout

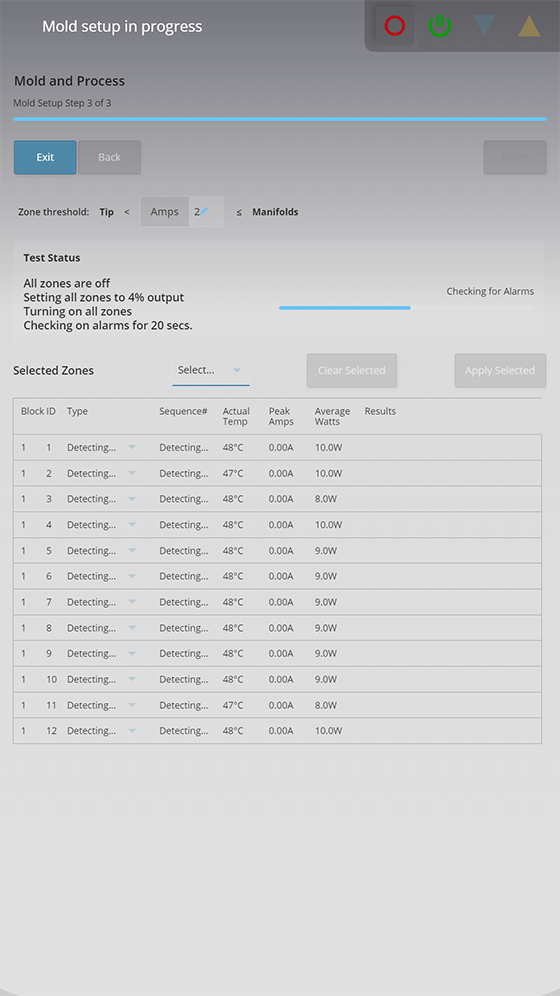

- Run Automatic Hot Runner Detection