Precision is more than a standard – it’s our identity.

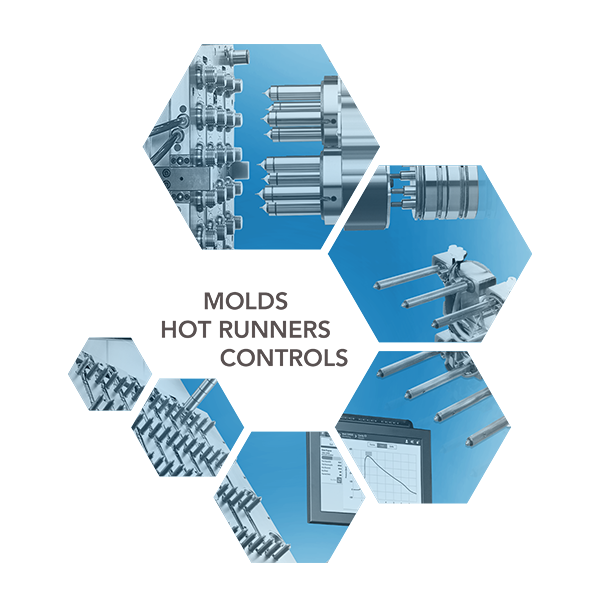

Since 1966, Gammaflux has been dedicated to engineering the most technologically advanced, high-quality temperature control systems for the plastics industry, particularly for hot runner systems.

We consider our customers not merely as buyers but as partners in achieving optimal productivity and cost efficiency. Our innovative control systems support precise temperature management, enabling high-quality parts, minimal scrap, and maximum profitability.

-1.png)

-1.jpg)

.png)

-1.png)

.png)