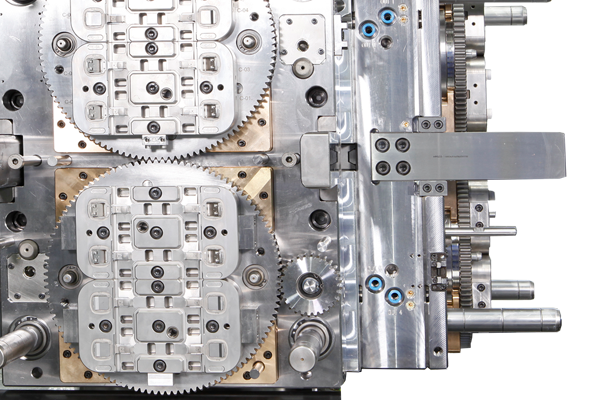

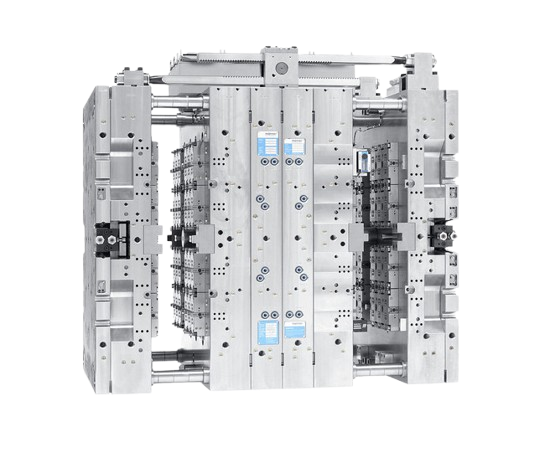

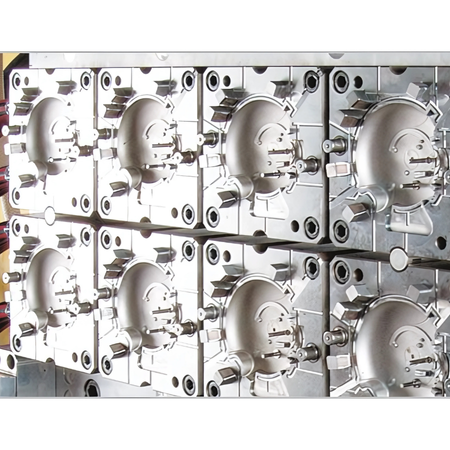

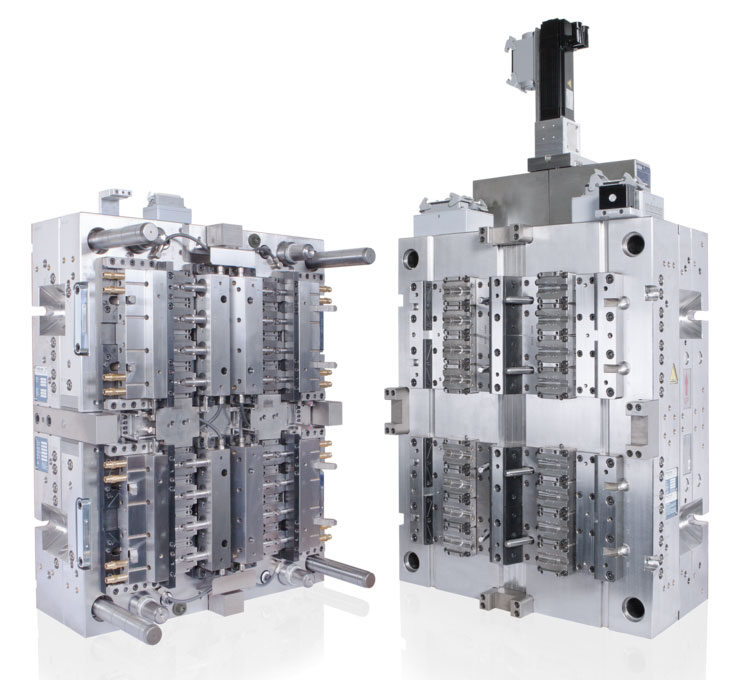

Molds trusted worldwide

When it comes to injection molds, precision and reliability are everything. With over 20 years of experience in mold design and toolmaking, we deliver solutions tailored to your specific requirements. Whether you need a prototype tool for testing or a long-lasting mold for mass production, our expertise ensures consistent quality and competitive pricing.

-

Unmatched Precision – Every mold is engineered with micron-level accuracy to guarantee flawless part quality and repeatability.

-

Extended Durability – Built with premium materials and advanced cooling systems, our molds withstand the toughest production environments and deliver a long service life.

-

Cost Efficiency – Optimized mold design reduces cycle times, minimizes waste, and lowers your total cost of ownership.

-

Faster Time-to-Market – With streamlined design, engineering, and manufacturing processes, we help you move from concept to production without delays.

-

Industry Expertise – Serving key markets including medical technology, packaging, automotive, and consumer goods, we know the specific challenges of each industry.

-

Global Support – Our international network ensures technical support and service whenever and wherever you need it.

%20(1000%20x%201000%20px)%201.jpg)

%20(1000%20x%201000%20px)%205.jpg)

%20(1000%20x%201000%20px)%203.jpg)

%20(1000%20x%201000%20px)%206.jpg)

%20(1000%20x%201000%20px)%204.jpg)

%20(1000%20x%201000%20px)%202.jpg)

.jpg)

.png)