Hot Runner Configurator

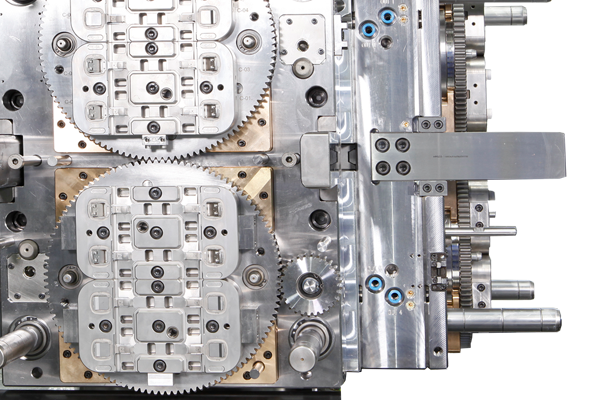

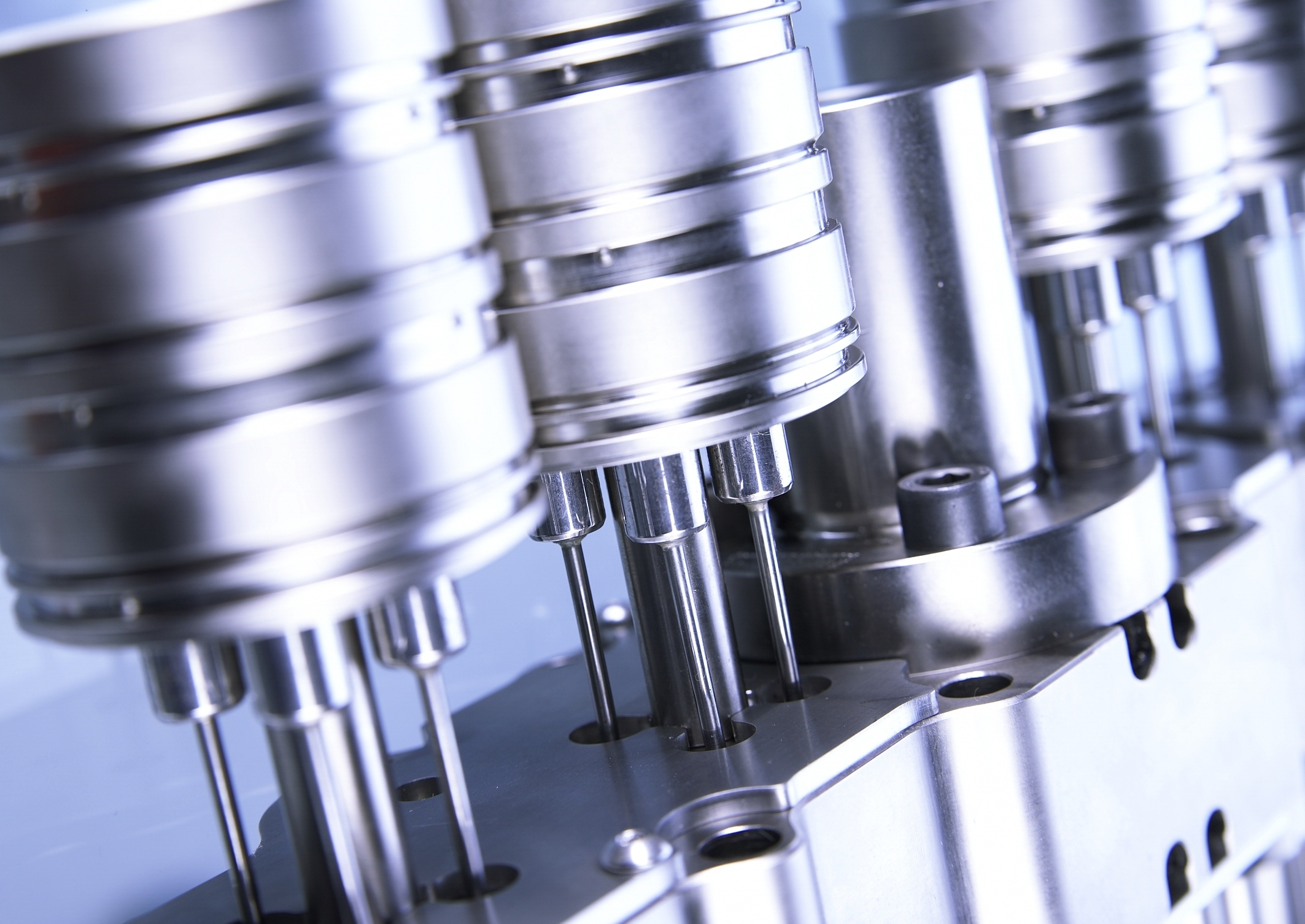

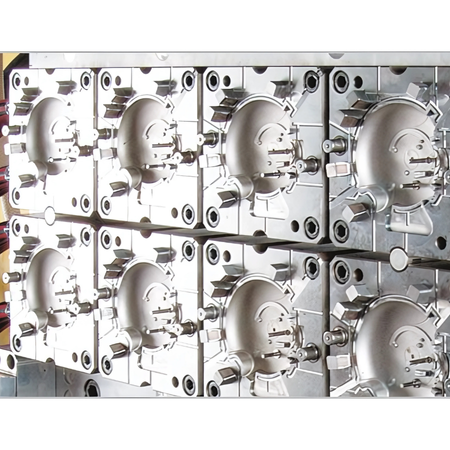

Hot runner technology plays a crucial role in the success of any injection molding project. Each plastic product requires a tailored design and implementation to meet its unique requirements. While many claim to offer hot runner solutions for every application, Barnes Molding Solutions truly stands apart.

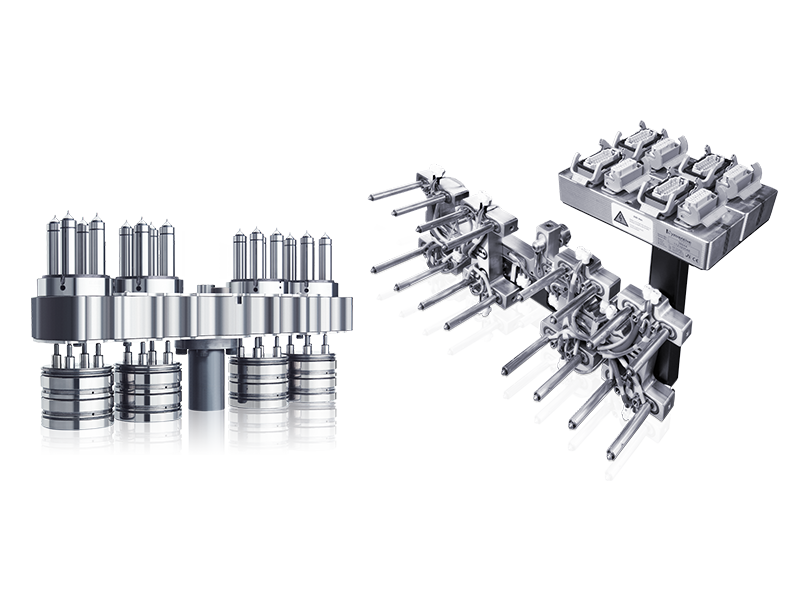

With dedicated experts for each market, our team brings decades of in-depth experience, enabling us to fully understand the challenges of your industry and deliver the most technically and economically efficient solutions. Our brands – Männer, Synventive, and Thermoplay – each offer distinct technical concepts tailored to the specific needs of different markets.

This unique approach allows customers to choose the technology that best fits their injection molding project while benefiting from a single point of contact and knowledge sharing across all our brands. At Barnes Molding Solutions, we ensure your success through innovation, expertise, and collaboration.

.jpg)

.png)