侧喷射门

Simple. Reliable. Sustainable.

Lateral injection molding is significantly advantageous for tube shape components such as pipettes, syringes, caps and technical components.

User Friendly Thermal Hot Runner for Direct Side Injection

The Difference at a glance:

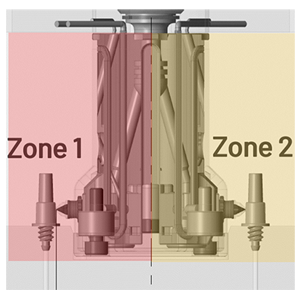

The best thermal separation:

Less Energy Consumption.

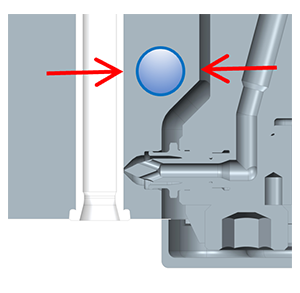

A circular seal between the nozzle tip and the mold ensures thermal separation. The resulting low heat transfer into the cavity leads to reduced energy consumption and enables shorter cycle times.

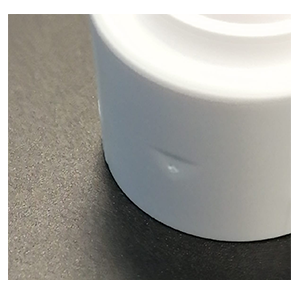

For cosmetic gates:

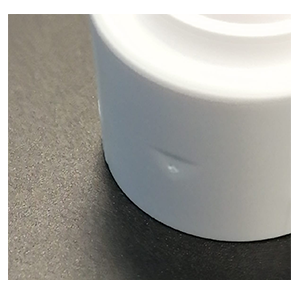

Barely Visible Injection Point.

The cylindrical seal is not only responsible for thermal separation but also for creating gate points that are hardly visible, with diameters in fractions of millimeters. The injection point can be placed in the visible area.

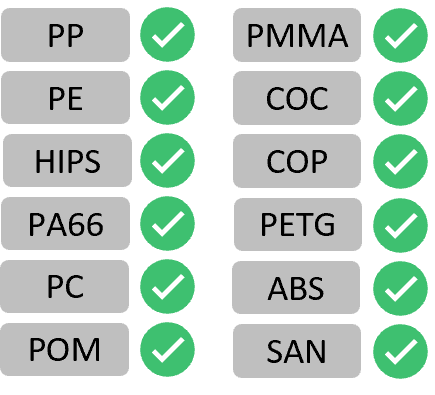

For technical resins:

Loves Demanding Plastics.

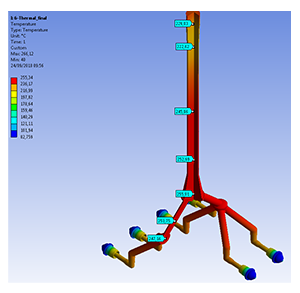

The THS Side Gate can do more than just processing standard materials. Even with highly glass fiber-reinforced and mineral-filled plastics or materials with narrow process windows, the nozzle impresses with a homogeneous temperature profile.

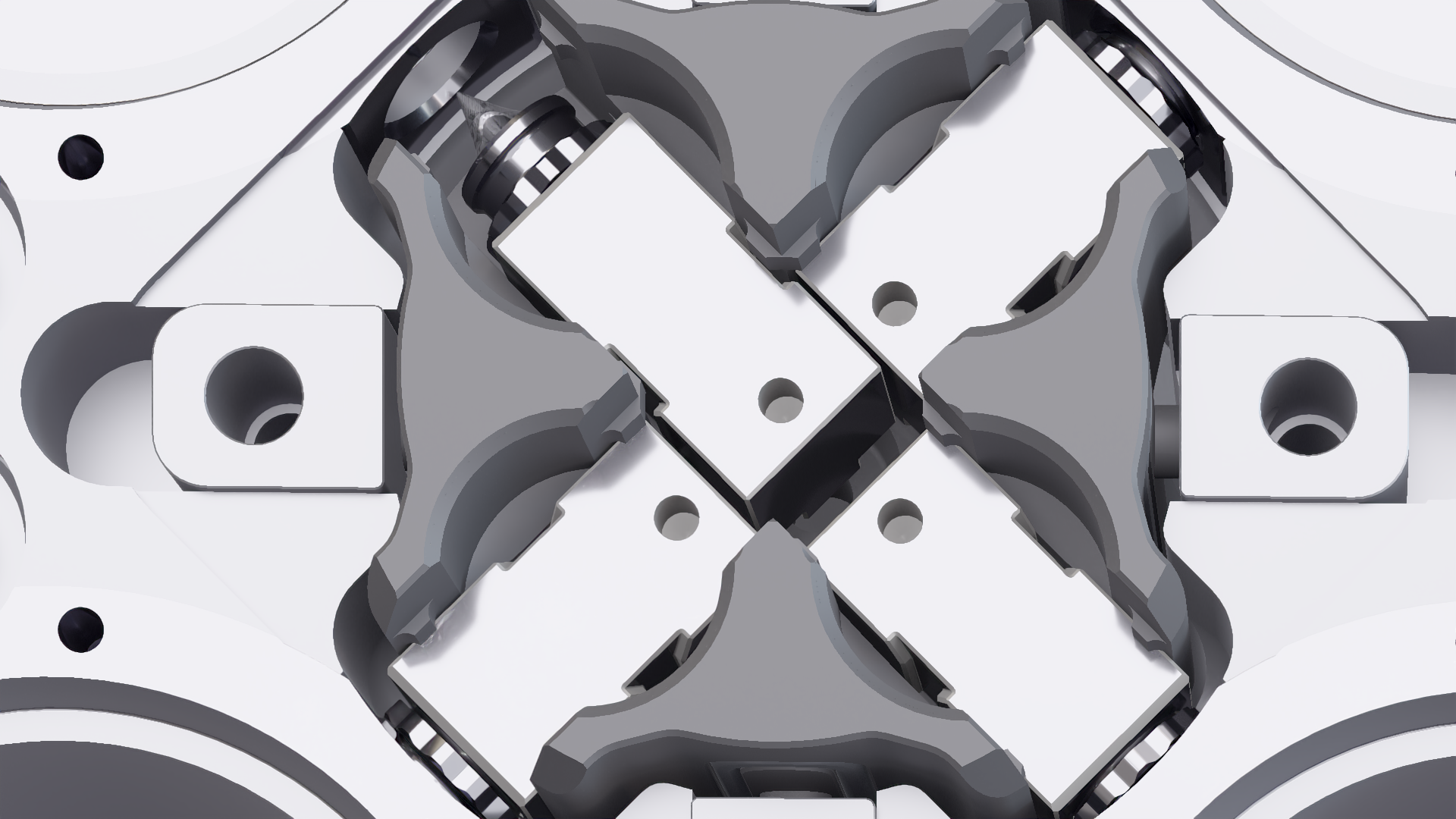

Easy Maintenance:

Tip Change in 8 Minutes.

Since side gate nozzles protrude into the mold insert, it is crucial for the user to know how challenging the disassembly is during maintenance or when a fault occurs. Eight minutes—that's how quick the time is to change a nozzle insert, with the mold remaining on the machine. And if necessary, a cavity can be shut down just as quickly and easily to keep production interruptions as short as possible.

Patented Heaters:

Homogeneous Temperature.

The homogeneous temperature profile in the nozzle is crucial, especially when processing technical or sensitive materials.

The focus during the development of the nozzle was therefore on the heating design. The THS is equipped with patented heating elements from Thermoplay, which have already proven their efficiency in countless applications.

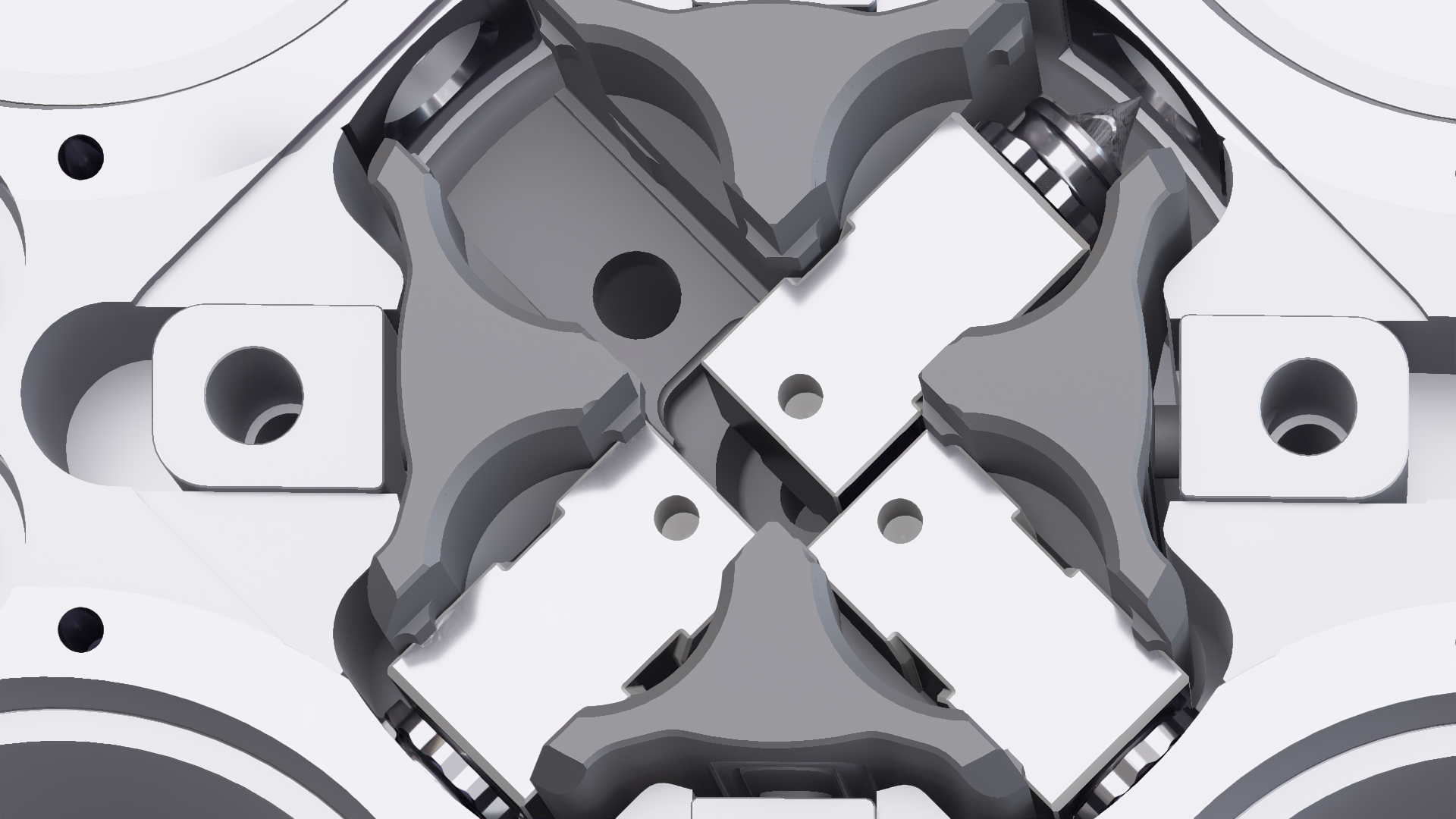

Perfect Filled Cavities:

Individual Tip Control.

The best option for the ideal balance of fill in multicavity applications.

At the same time, precise temperature control allows for the processing of a wide range of materials, including highly glass fiber-reinforced and mineral-filled plastics with narrow process windows.

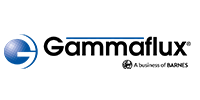

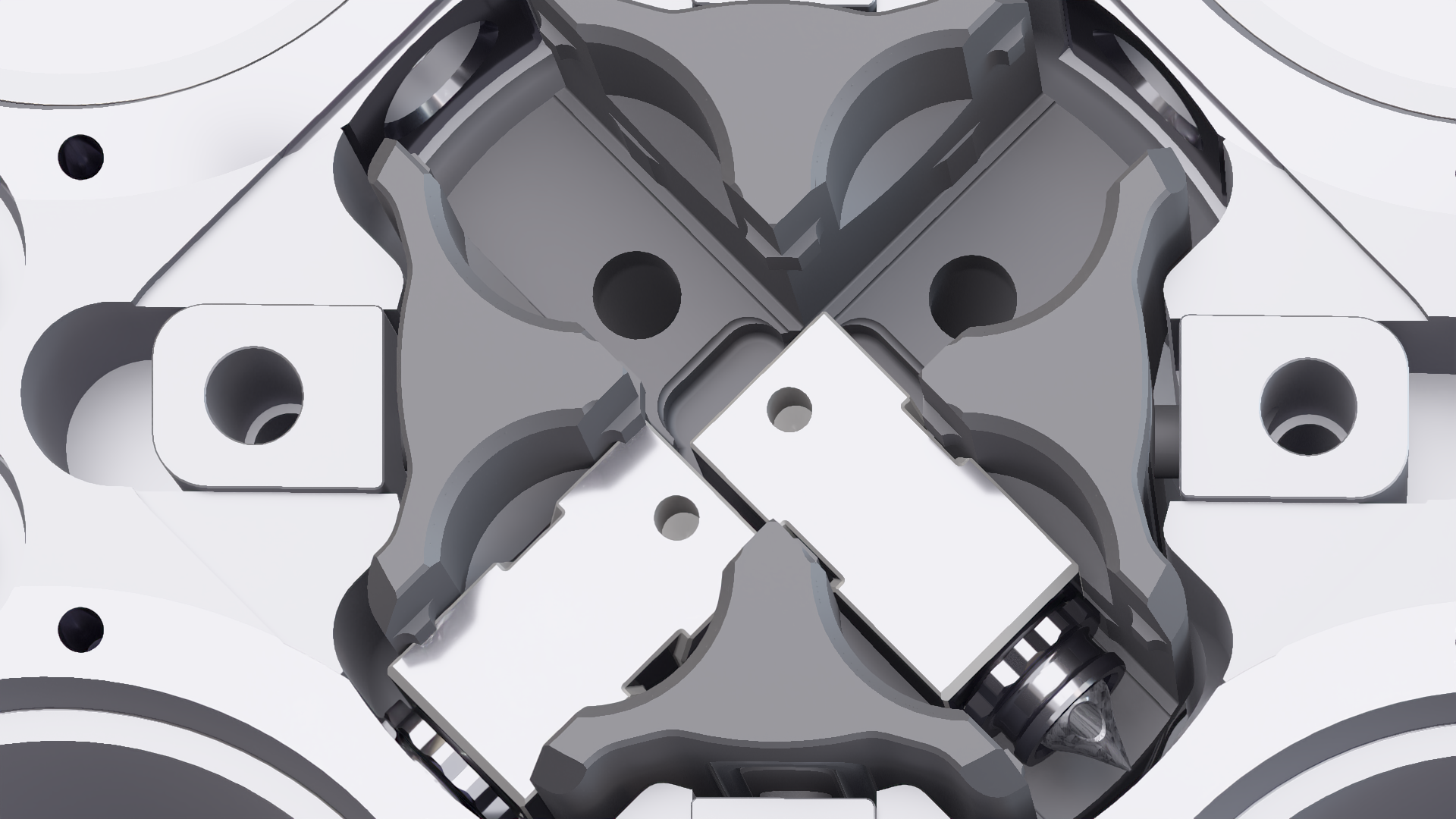

Radial Version (THS-Radial):

- 1, 2, 4 or 8 nozzle tips.

Linear Version (THS-Linear):

- 2+2 or 4+4 parallel nozzle tips.

- Minimal gate point spacing of 16 mm.

- Particularly suitable for applications requiring multiple injection points in a row.

Widely used in all multi-cavity injection molding fields:

Medical

Personal Care

Packaging

Electronic

Easy Maintenance.

Since side gate nozzles protrude into the mold insert, it is crucial for the user to know how challenging the disassembly is during maintenance or when a fault occurs. Eight minutes—that's how quick the time is to change a nozzle insert, with the mold remaining on the machine. And if ever necessary, a cavity can be shut down just as quickly and easily to keep production interruptions as short as possible.

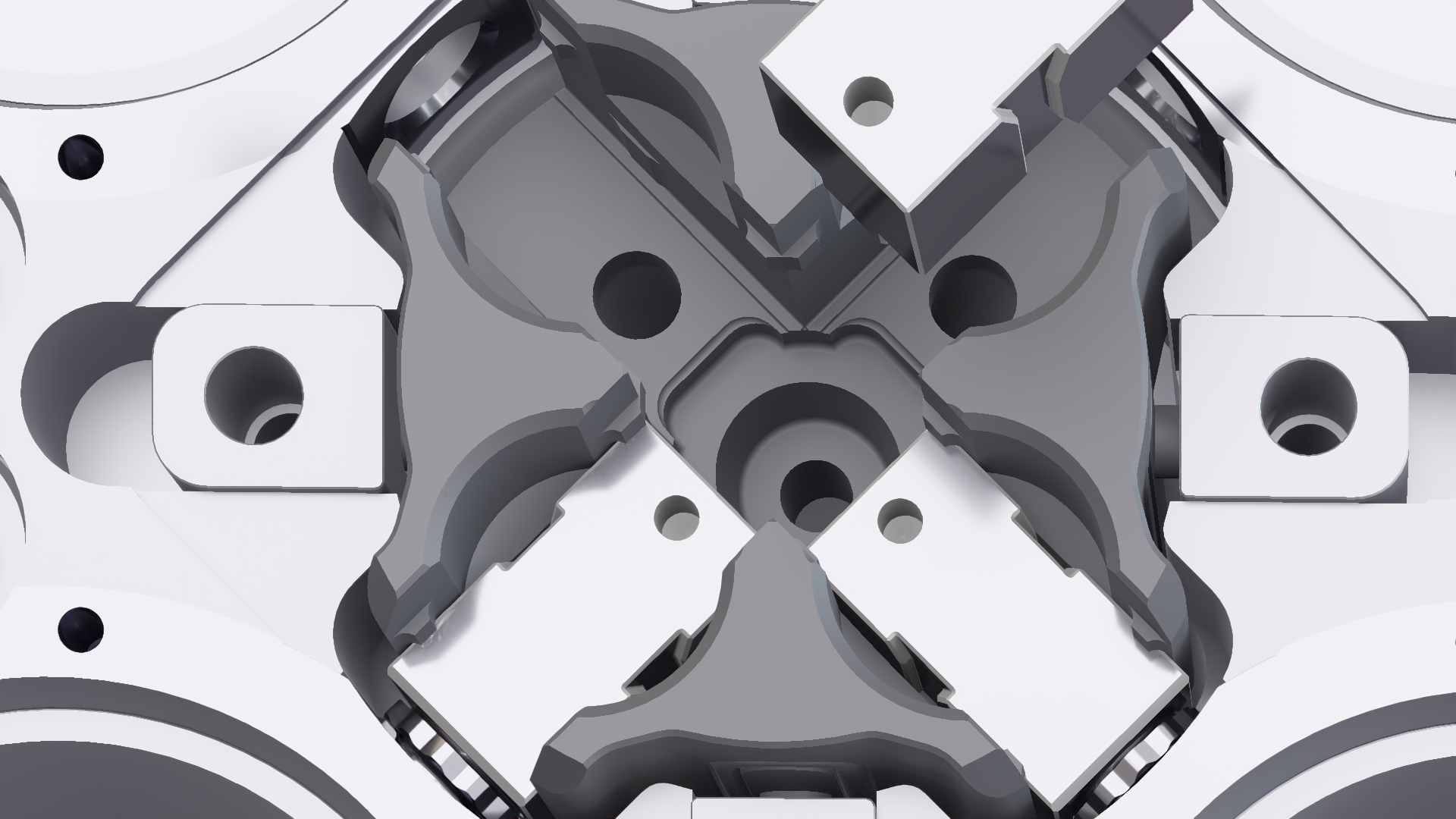

Side Gate Solutions Overview

Cylindrical tip/cavity sealing. No thrust from nozzle to cavity, lowest power consumption, no heating sequence required, sealing guaranteed also in cold conditions.

Individual tip temperature control.

Naturally

balanced

Barely visible

gate vestige

Space for

effective cavity

cooling

Can process nearly all the resins (even with glass/mineral fillers)

Naturally balanced

Barely visible gate vestige

Space for effective cavity cooling