.png)

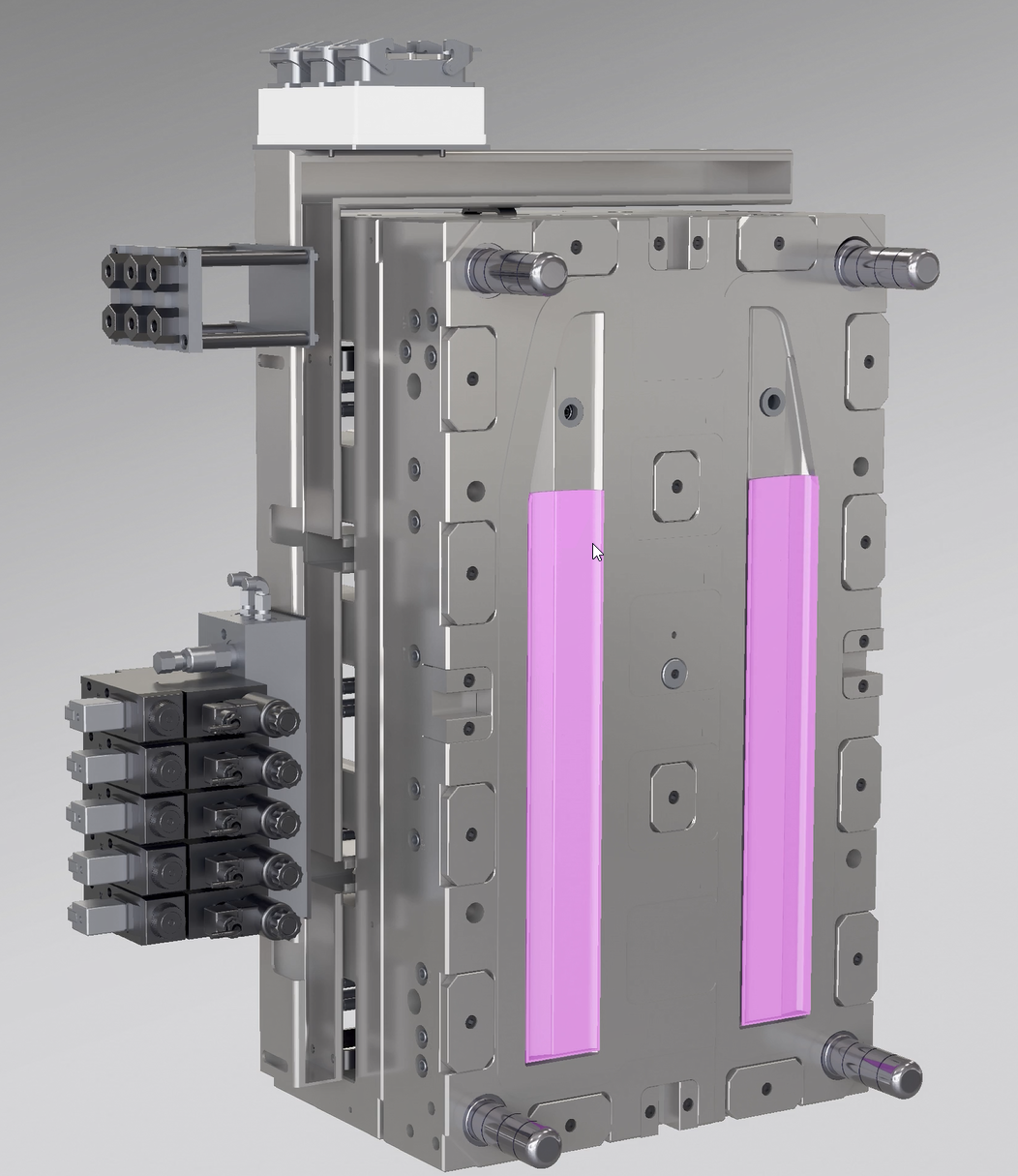

Sequential (Cascade) molding processes are usually controlled by the screw position, time or cavity sensors. The exact timing of the nozzles is determined by experienced operators during mold sampling. Depending on the component and mold, this process can take several hours.

Save time and money by using sensor technology that automatically leads to an optimized injection molding process. Have you been avoiding the use of sensor technology because tool processing and installation are too time-consuming?

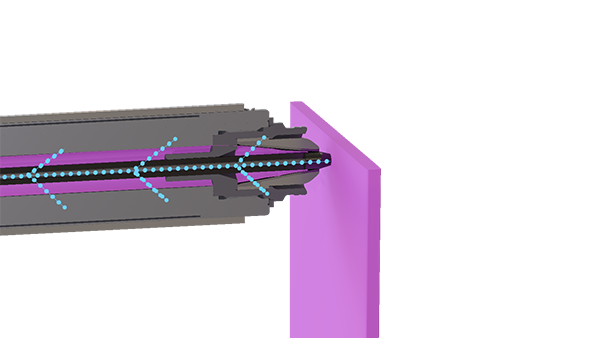

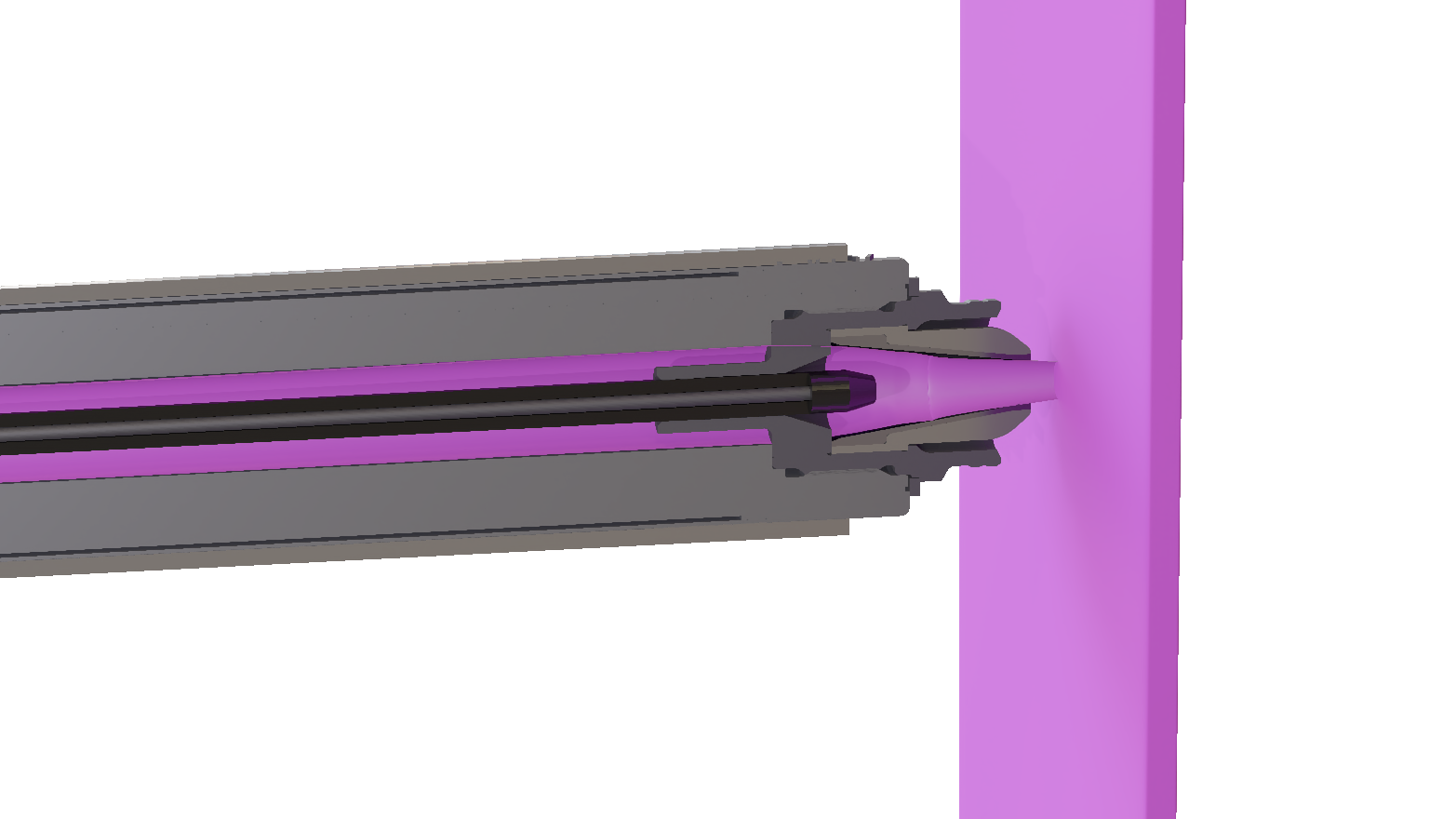

We have the solution: Introducing IntelliGate, the first plug-and-play system of its kind. In Synventive's new system (patent pending), the pin provides a fully integrated sensor technology that locates the melt front. The valve pin in the relevant nozzle then fully opens automatically. The ideal process is thus quick, efficient, and virtually risk-free, since IntelliGate comes fully pre-installed, wired, and tested.