Fuboha offers a versatile portfolio of Cube Mold technologies — each engineered to meet specific requirements in part complexity, output volume, cycle time, and machine footprint. Whether you’re scaling up production, integrating multi-material molding, or optimizing for limited space, our cube systems deliver high-performance results with unmatched efficiency.

Use the table below to compare key features and find the solution that fits your production goals.

| Technology |

Cavity Count¹ |

Footprint / Size² |

Cycle Time³ |

Key Feature⁴ |

Best Suited For⁵ |

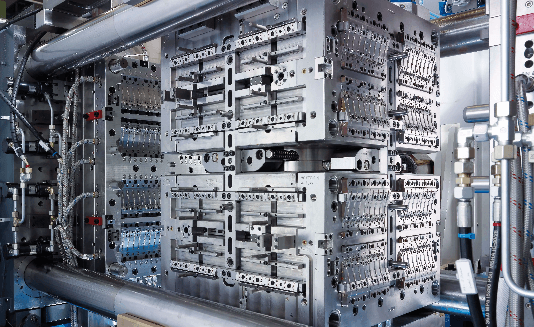

| Single Cube Molds |

High |

Medium |

Short |

Parallel processing steps |

High-volume production |

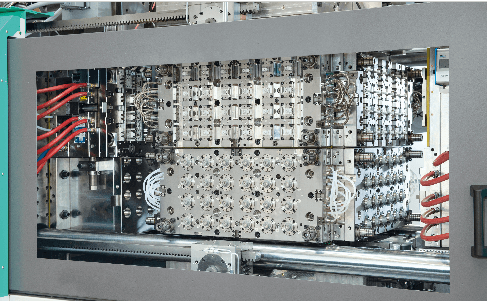

| Indexing Cube Molds |

High |

Medium |

Short to Medium |

Precise index movement for accuracy |

Multi-material parts, complex geometries |

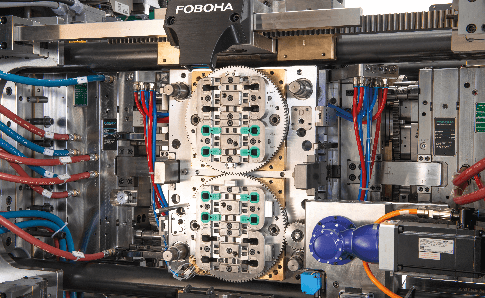

| Reversecube Molds |

High |

Large |

Medium |

Counter-rotating cubes for design flexibility |

Advanced designs, multi-component molds |

| CITI Cube Molds |

Medium |

Very Compact |

Short |

Integrated, compact technology |

Retrofits, space-limited setups |

| Stack Turning Molds |

Very High |

Large |

Very Short |

Multi-stack output, same footprint |

High-output packaging & medical applications |

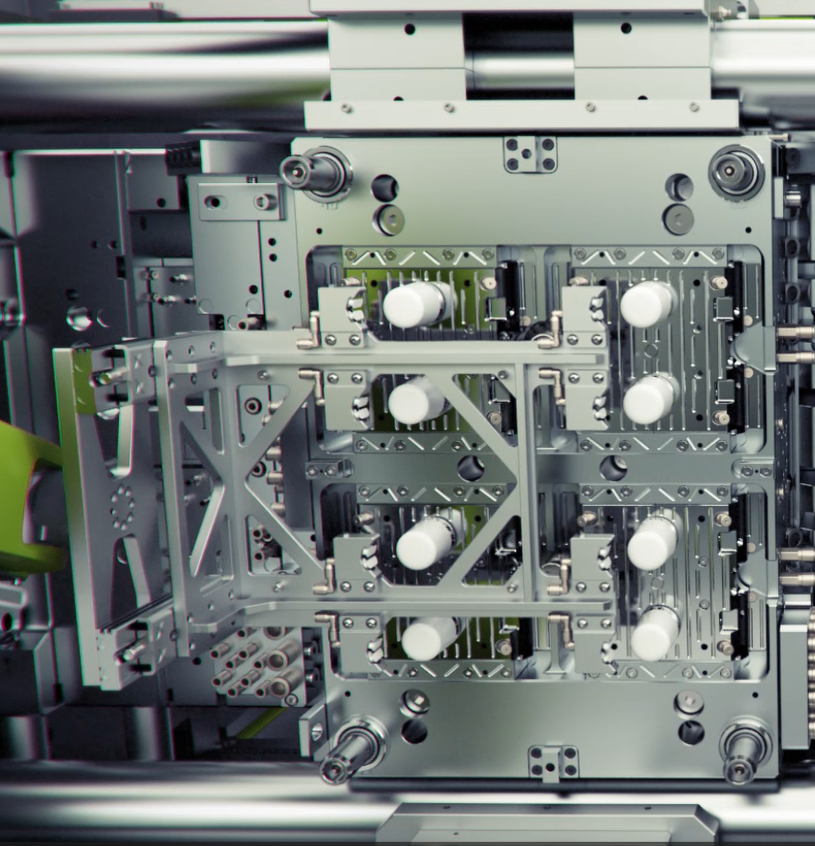

| Compact Cube Molds |

Medium |

Compact |

Short to Medium |

Full performance in compact size |

Small machines, tight production cells |

¹ Cavity Count: Relative to machine size and product geometry

² Footprint: Refers to the required installation space for the mold on the injection molding machine

³ Cycle Time: Depends on material selection, part design, and machine configuration

⁴ Key Feature: Describes the unique selling proposition or primary technical advantage of each mold type

⁵ Best Suited For: Indicates the most appropriate industry or application based on the mold's strengths