Live Demonstrations

Look forward to exciting live technology at interactive demonstrations in our Tech Center, where you’ll see innovations up close and firsthand. Don’t just observe the latest innovations—immerse yourself and experience them live:

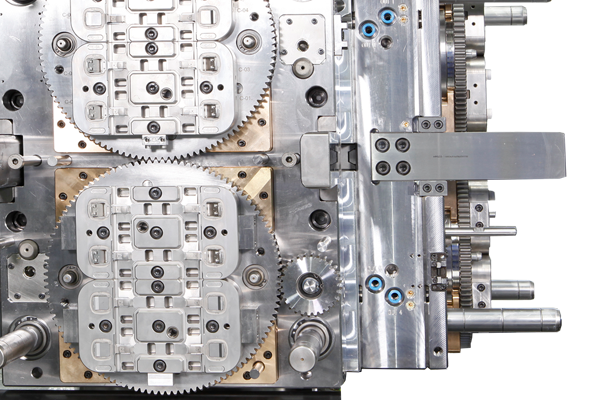

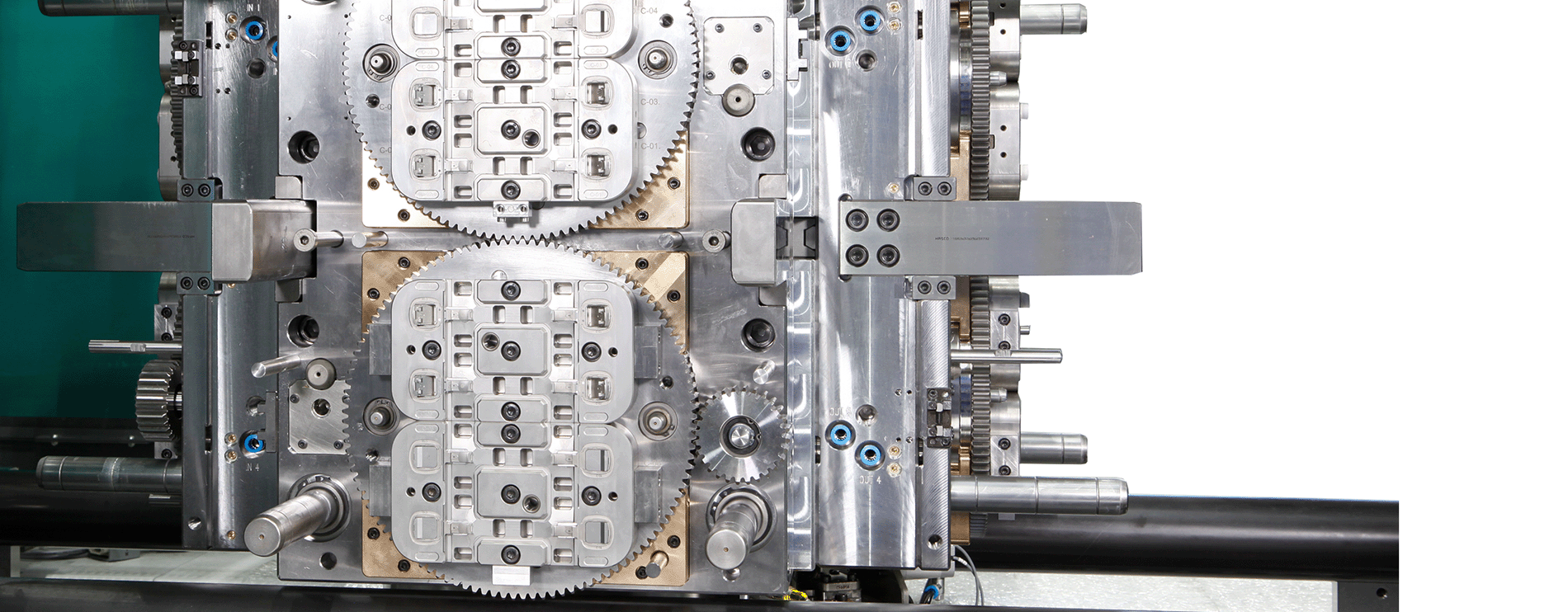

- High Cavity Molding

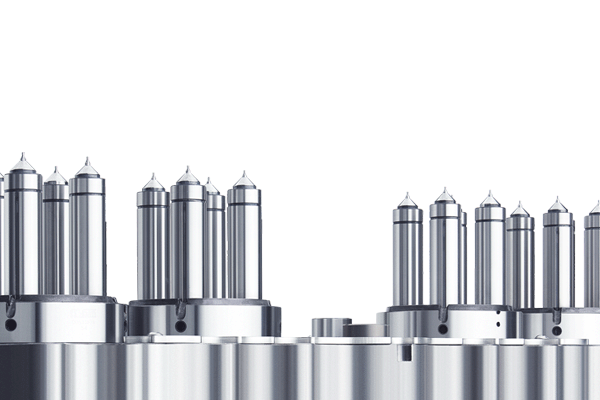

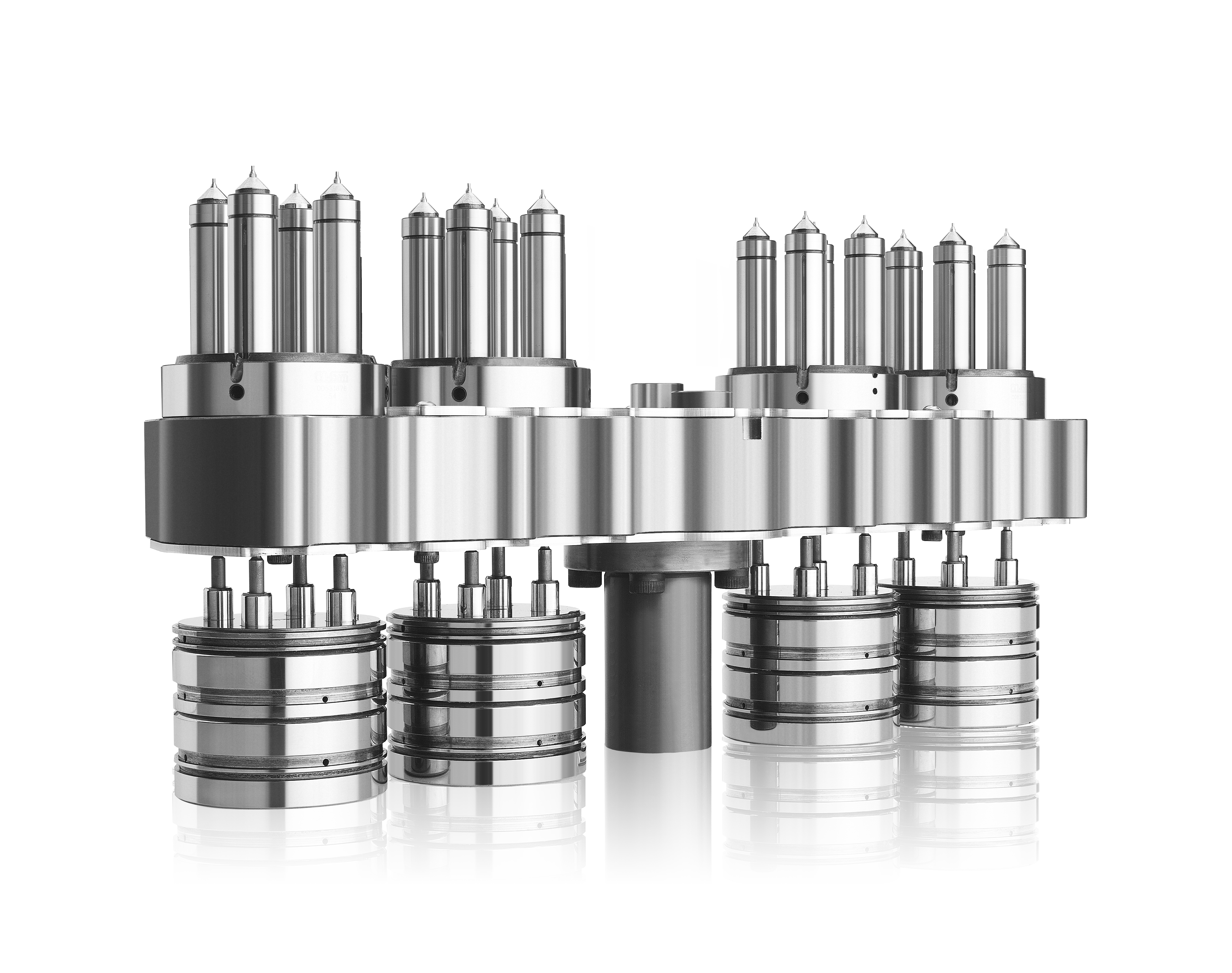

- Fast Pipette Tips Production

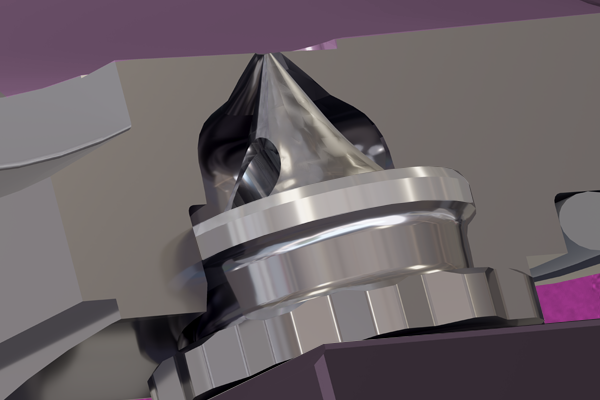

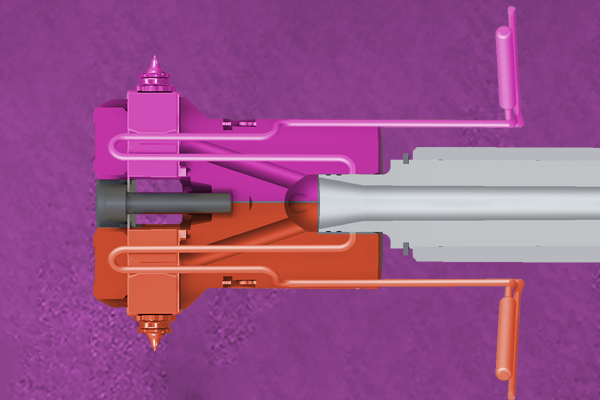

- User-friendly Side Gating

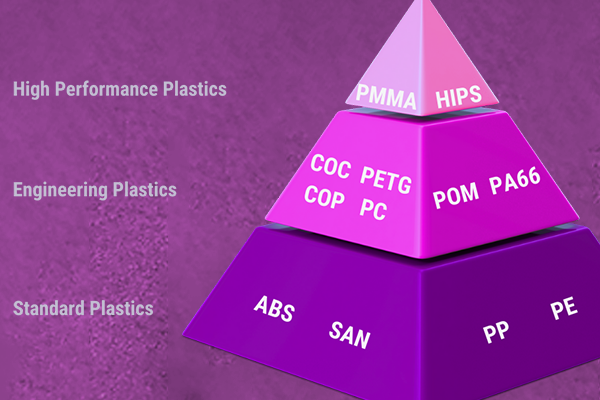

- PVC & More - Medical Materials